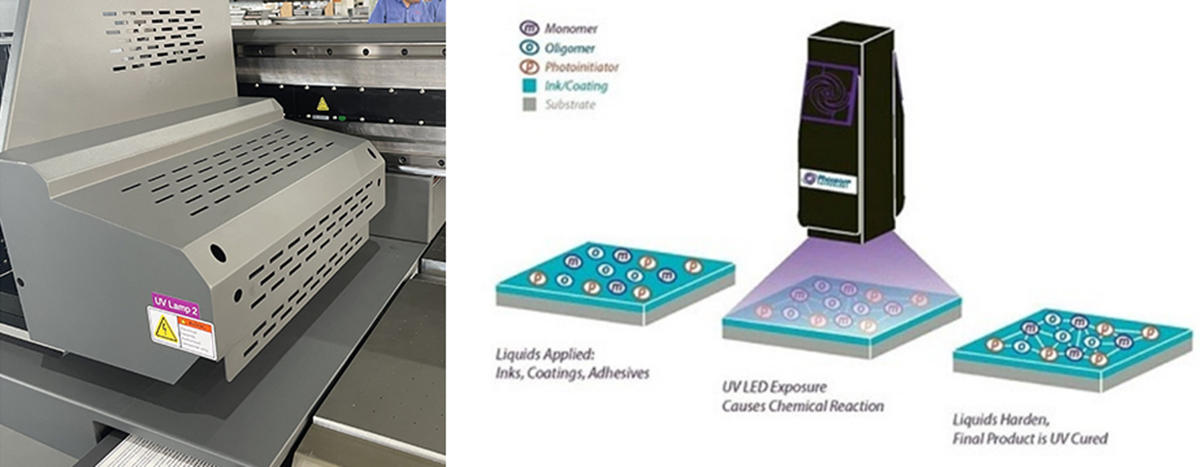

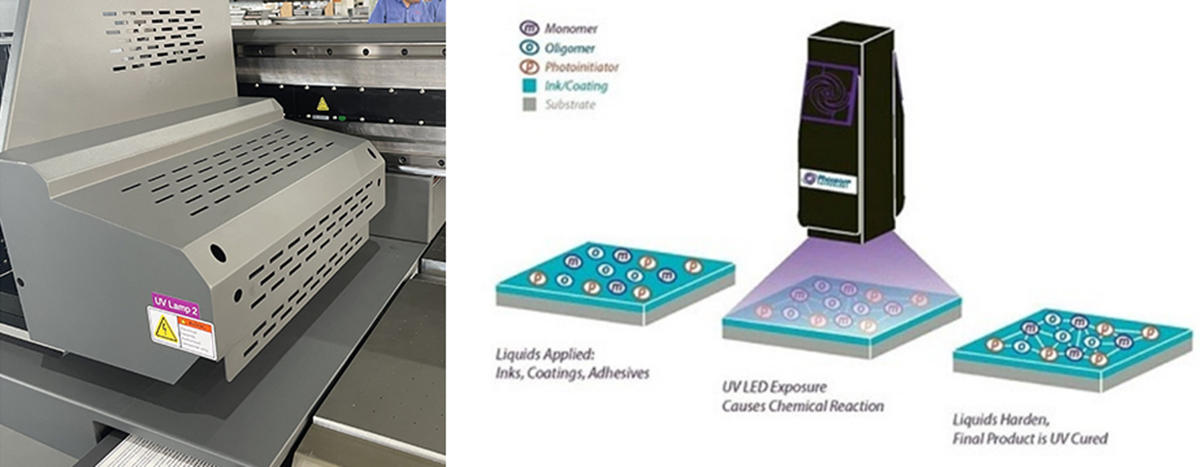

Ink Curing System

Ink curing system operates with water-cooling Led UV lamps, which is with longer lifetime, more silent operation, never make ozonic gas and emit less heat comparing with traditional mercury lamps. It enables user to have more media choices, printings on sensitive or non-sensitive materials and printings withvarnish implementation as well as to save energy, costs and time. With the use of VOC (Volatile Organic Compounds) the UV curable ink is environmental friendly and no bad smell. Drawer-type UV lamp cassette makes it easy to replace the lamps when needed. DOCAN Unique 5 dgree BANK Angle design avoids heads' harm.

Vacuum Table & Registration Pin

Combining with sheet-to-sheet with roll-to-roll printing functions, a large-sized vacuum table is for accurate feeding the medias. The maximum material width is 320 cm and length is 205 cm. Table with pneumatic collapsable linear alignment pins for easily position the rigid medias. Air compressor connection is required to operate the system. X axis has 5 and Y axis has 4 pins. H3000 RM can easily switch from flatbed to roll-to-roll mode with a click from the software.

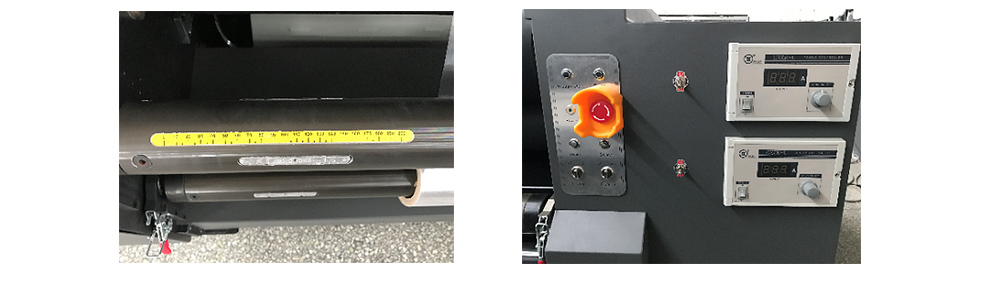

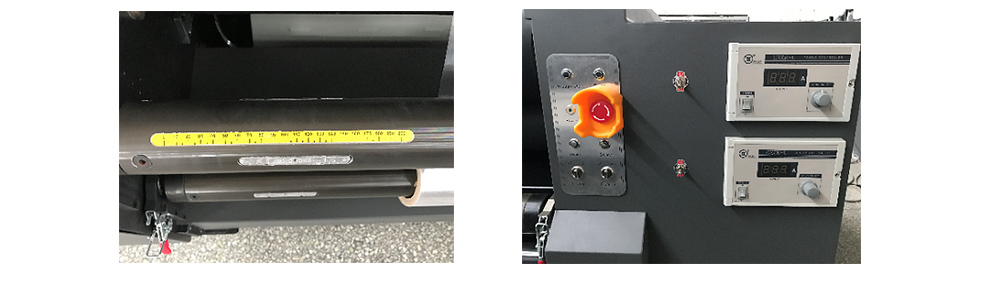

Winding Roller

Inflatable winding roller for releasing and collecting the flexible medias. Roller tension control panels on the front frame is to adjust the rotational speed.

5-zone Air Suction and Reverse

Two Powerful vacuum pumps for 5-zone air suction of the vacuum table. With respective control buttons, a pedal switch makes it capable to reverse air blowing function for lifting the heavy medias easily(Optional). The Honey-Comb table and internal air pipe ducts for efficient and powerful distribution of vacuum effect.

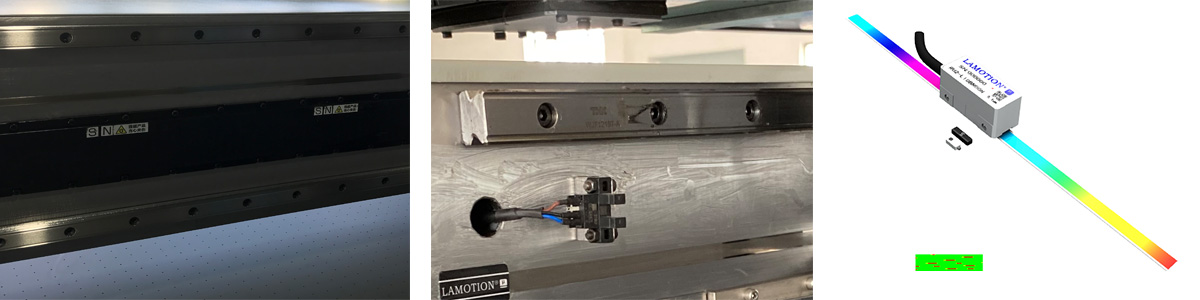

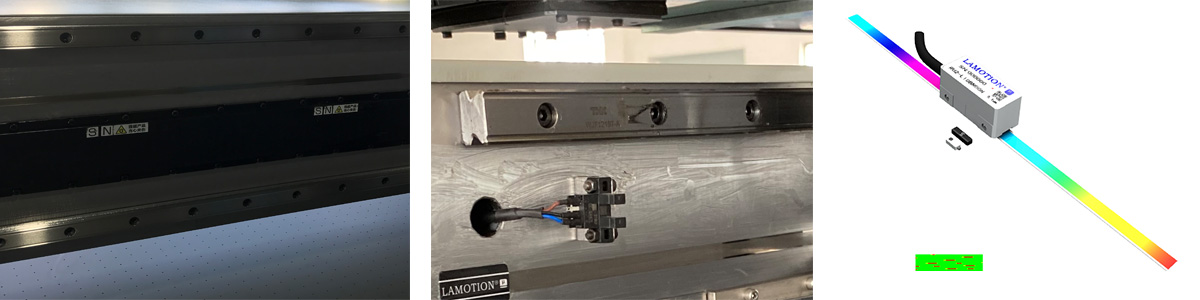

Guide Rail & Metal Liner Raser

Equipped with linear motor in higher precision, efficiency and stability, Japanese THK silent guide rail and X axial metal raster ensures straight carriage moving to achieve accurate printing and posibility of high driving speed. Y Asix is driven by dual Delta motor belt system with Metal raster, which can control deviation within 1um.

Carriage Transport System

With advanced Automatic Height Detector, it can detect the material thickness and find a good height position for best quality printing. Anti-Crash and continue printing system can protect print head from crash and save media and time by continue printing. Thanks to the high-precision impact sensors on both sides of the carriage head transport mechanism, the print heads are not damaged from curled,swollen or surged materials. The mechanism has anti-static devices to prevent electrostatic effect that disrupts the image quality.

Ink Supply Unit

Automatic high-volume Ink Supply system ensures continuous printing. The white ink has automatic stirring and circulation system, which avoids the clog of white printhead. This system continuously circulates the ink between Sub Ink Tank, Main tank and internal main tank. It's equipped with Ink low level sensor, which can give users alarm once ink level is below than setting.

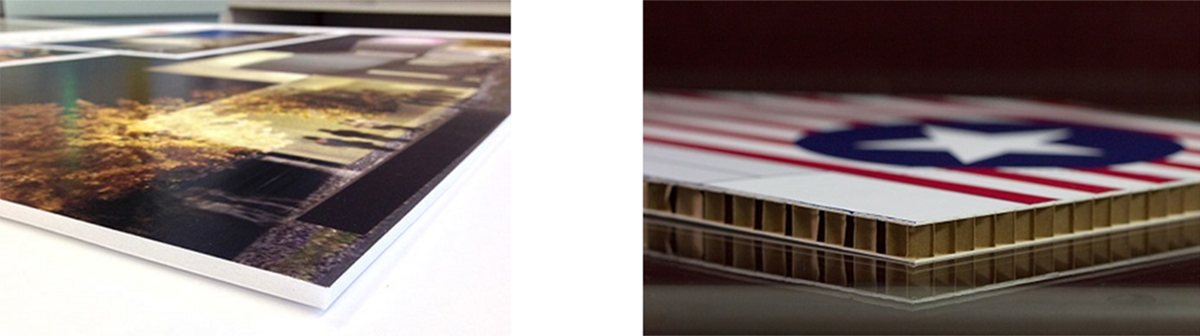

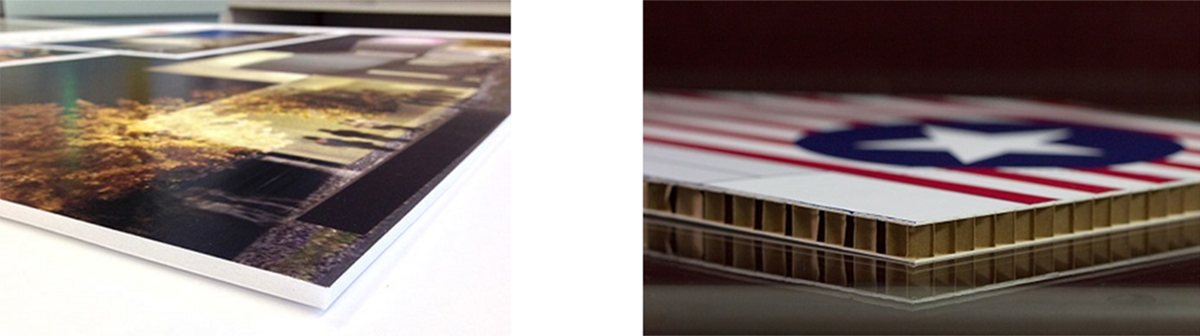

Direct Printing

Can print on up to 100mm thick substrates and the printing distance between the table and printhead can be raised more up to 200mm with an optional adaptor to print on thicker materials. It is possible to print on heavy substrates up to 100kg weight.

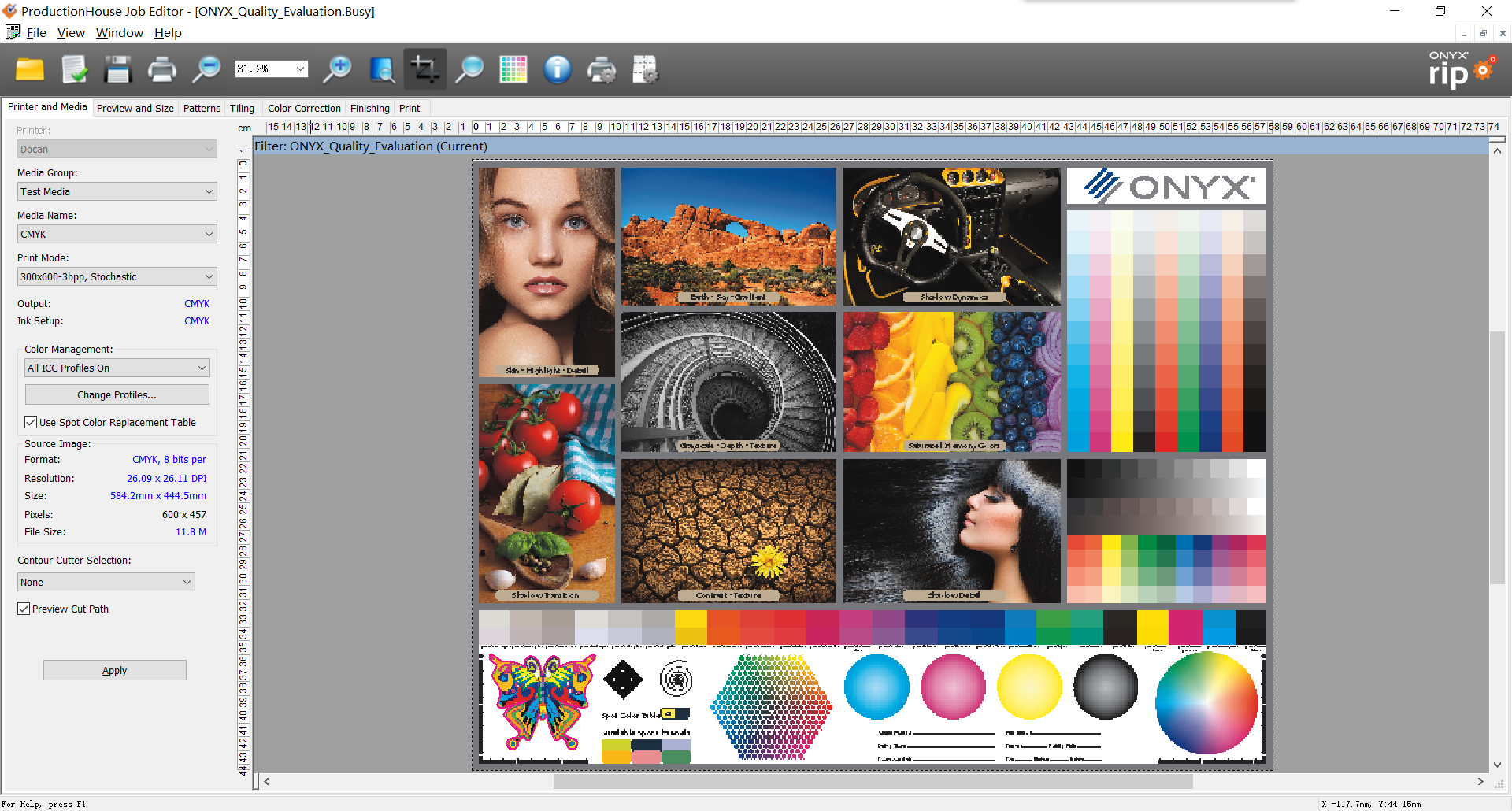

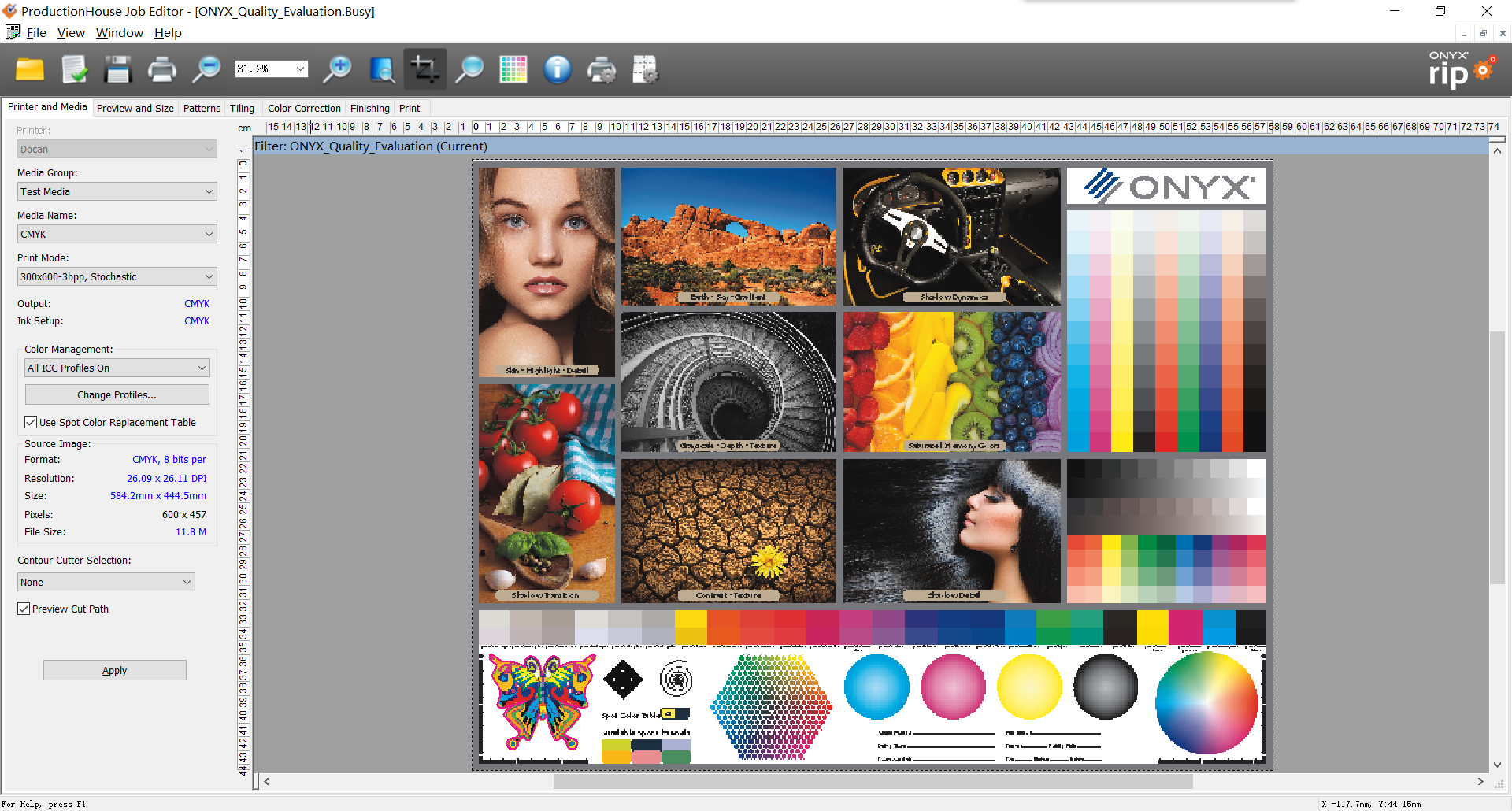

Rip Software

ONYX RIP Center is a standard software for Kyocera engine, which provides the control and simplicity need to get start in wide-format print production and achive consistent high-quality output. The versatile tools in ONYX RIP Center software make it easy to prepare jobs and produce sellable prints faster.

With advanced RIP technology, the user can get smooth gradients, vivid images and very clear small size text. The ICC color management workflow provides vibrant and bright colors.

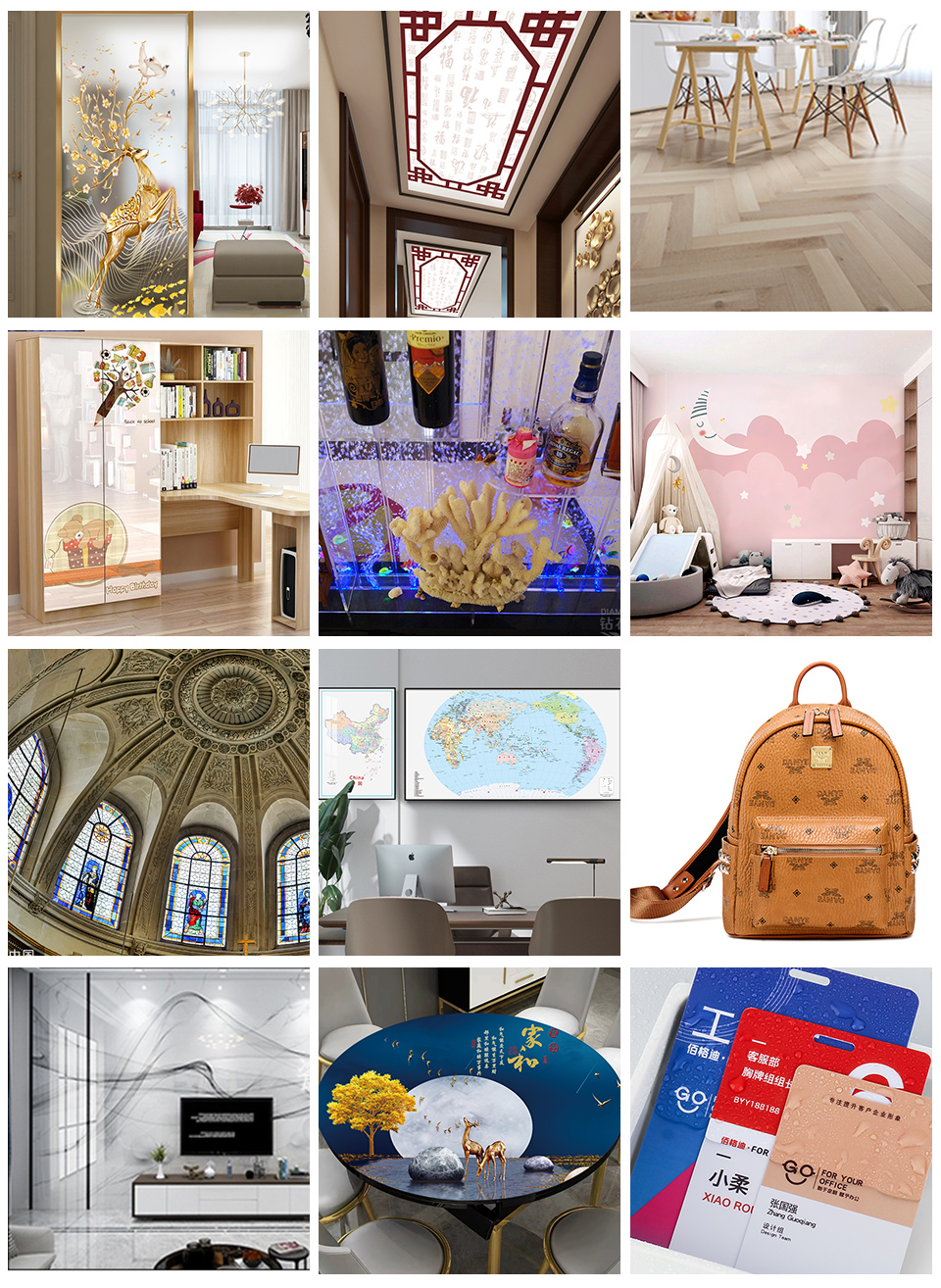

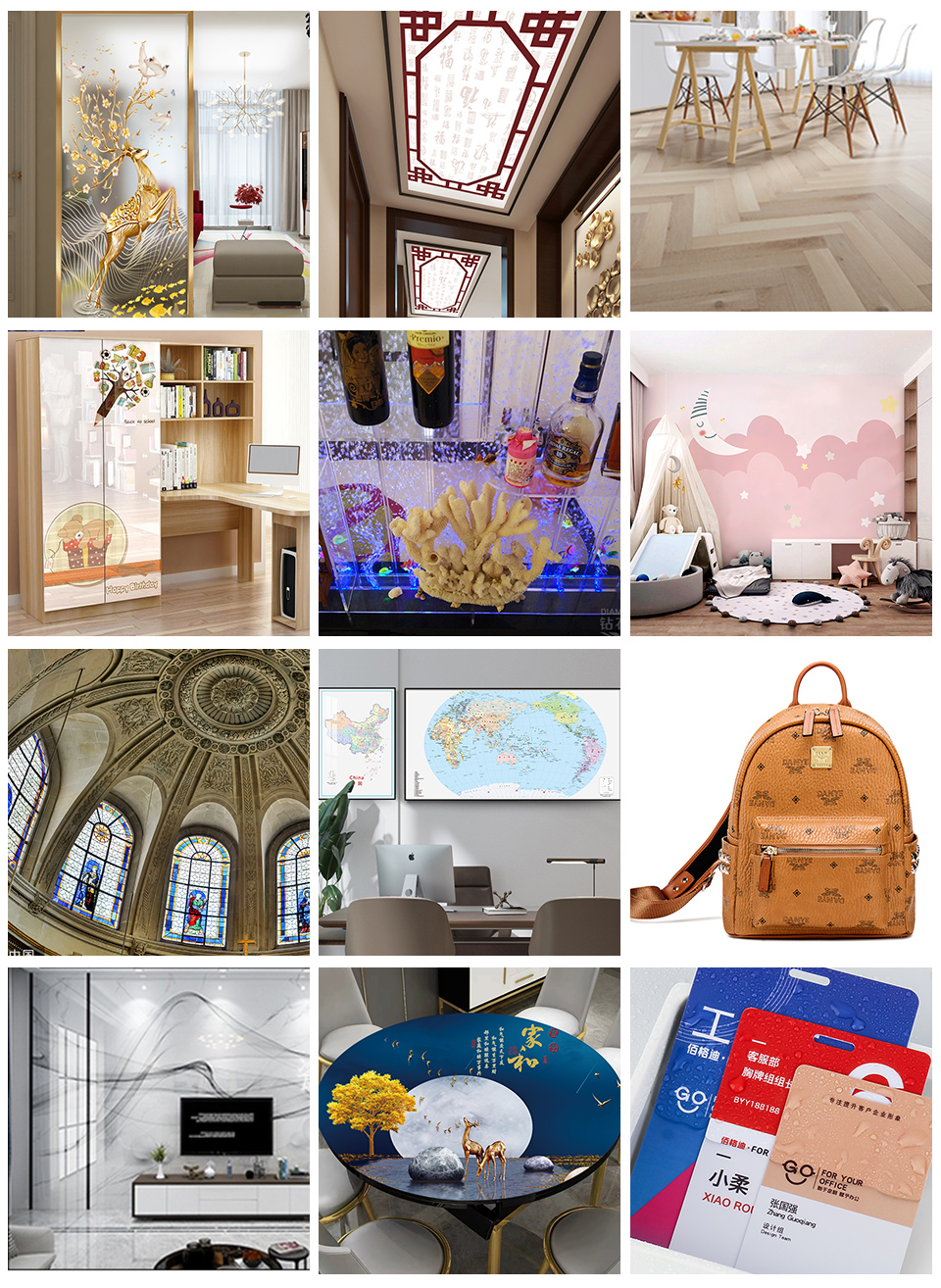

Example Applications

DOCAN · Shanghai

Since 2005