H1000 New Generation (Magnetic) (UV Flatbed Printer)(CCD OPTIONAL)

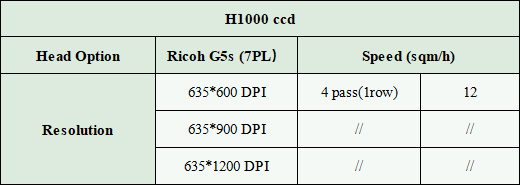

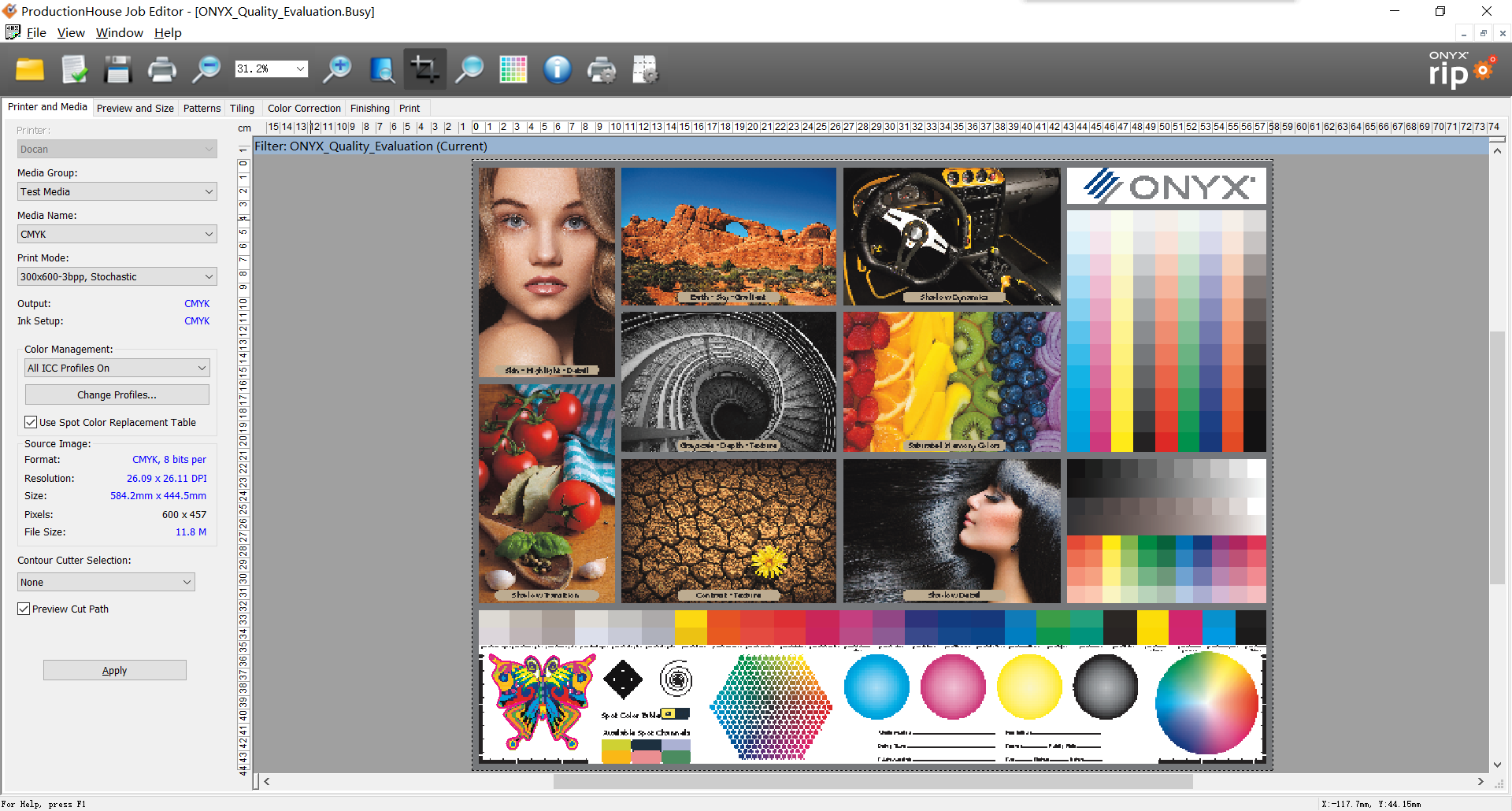

Colors: CMYK, White, Varnish, LcLm

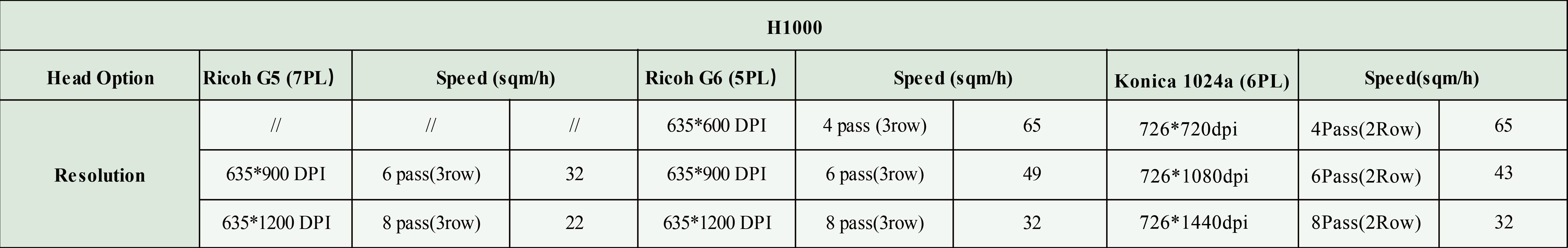

Printhead: RICOH GEN6 /GEN5/KONICA 1024A

Print Speed: Up to 45 ㎡/hr

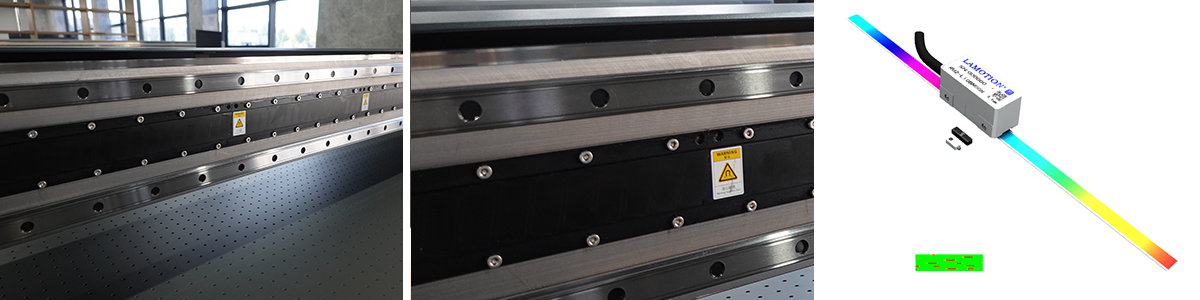

1.Linear motor driving 2.Anti-crash Sensor, Resume print after E-stop

3.Auto ink volum alarm system

4.Automatic Height Adjust System

5.White ink Recirculation System

6.Media vacuum suction system

7.Automatic Registration Pin System

8.Anti-static Bar

9.CCD OPTIONAL

H1000 has been verified by the market for 8 years now ushered in the third generation upgrade, this time upgrade first changed belt drive to linear motor drive, which increased X-axis motion stability and speed. Second, enlarged the carriage space whic in line with the current multi print heads demands.

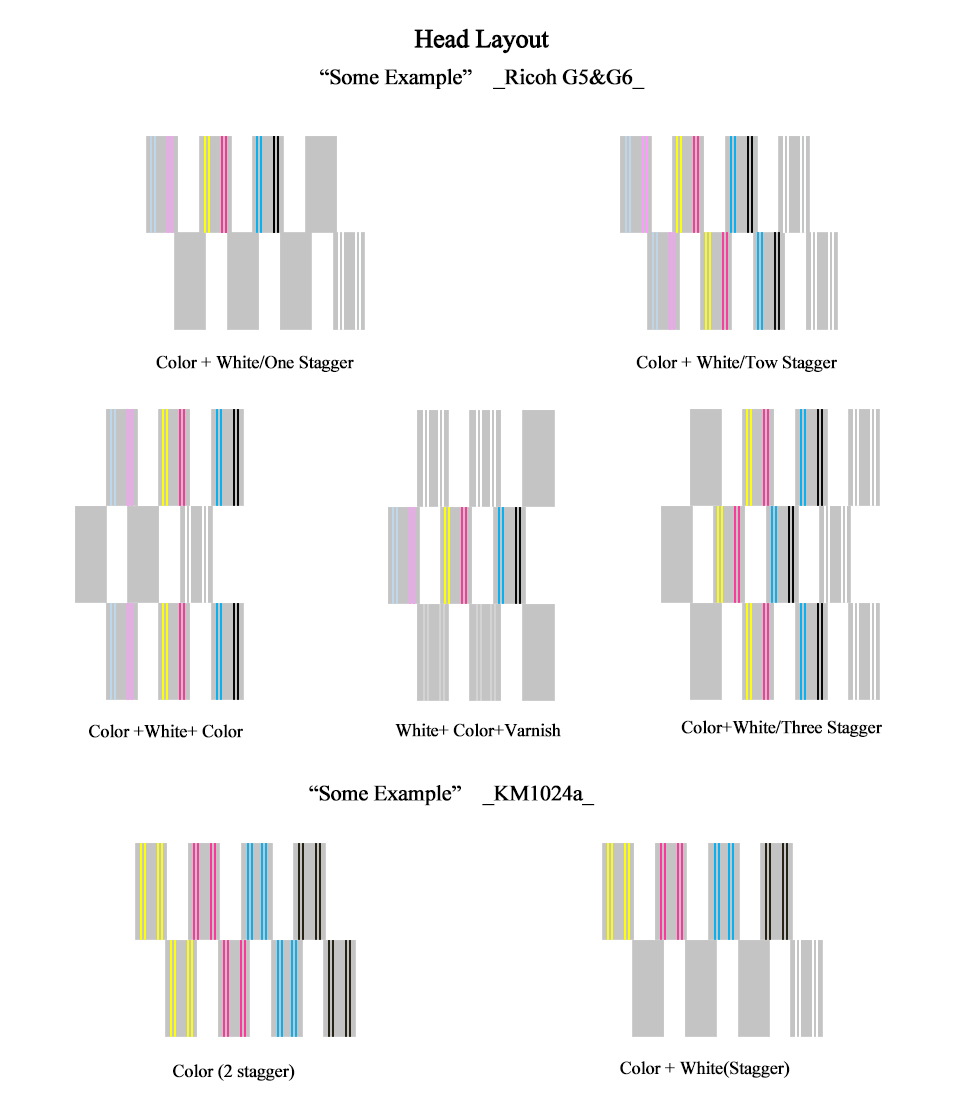

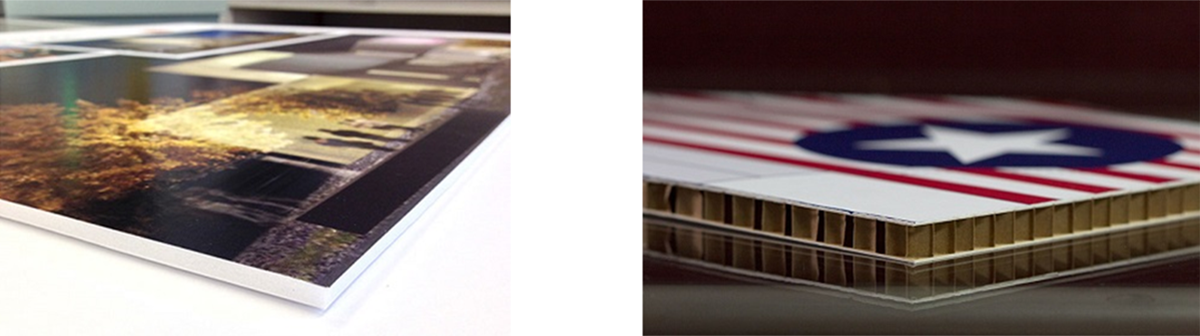

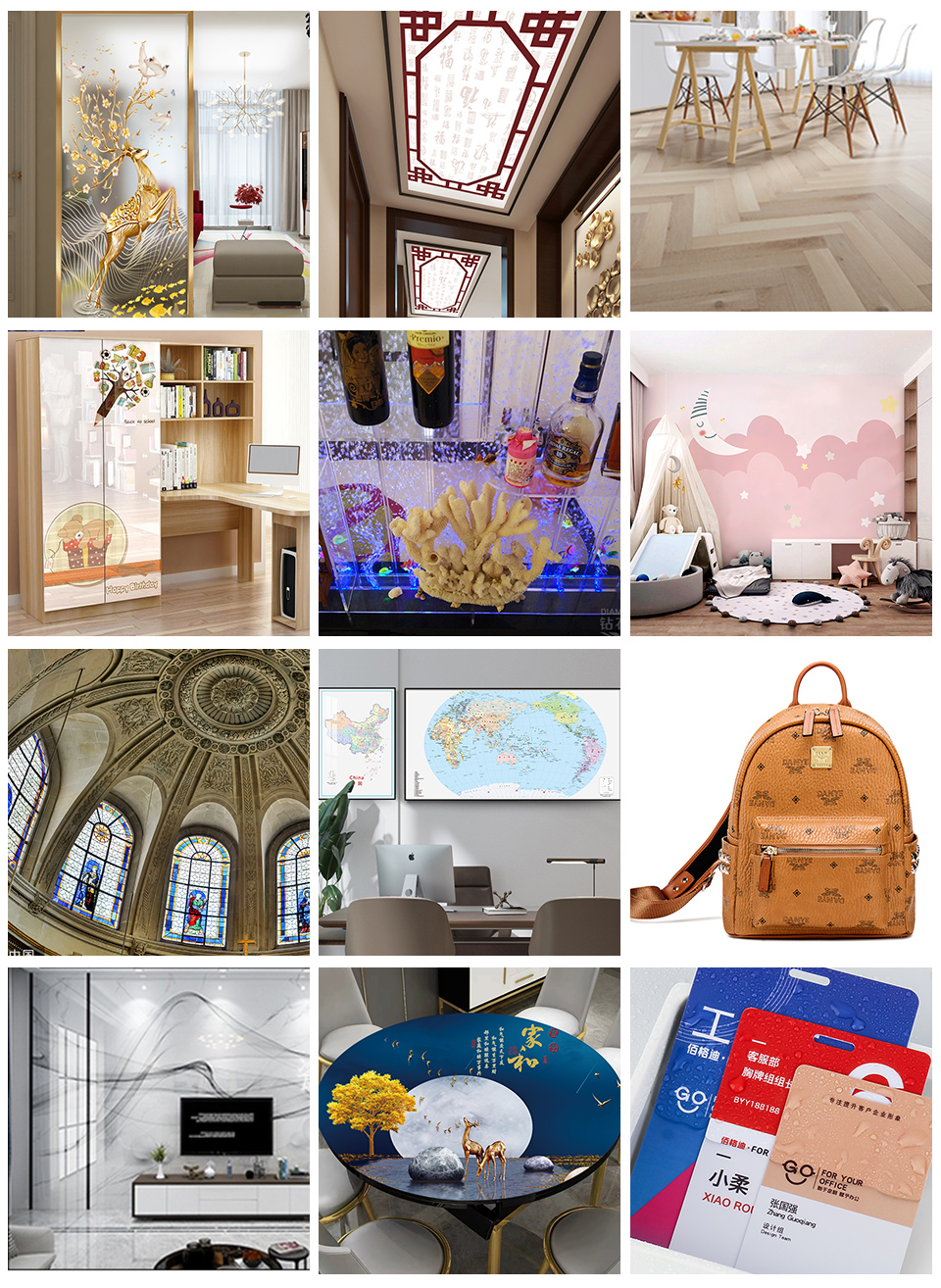

H1000 UV is aways the most comprehensive and innovative flatbed UV printer in our range. With its new designed and well structured case, THK guide rail and 2440 x 1220mm print area makes it as an ideal printer for facilities handling full-time industrial operations. It is able to print on heavy matel or wooden sheets up to 200 kg. Using the UV ink it can print excellent images on various rigid medias, such as glass, acrylic, wood, PVC foam board, KT board, MDF, aluminium, cellphone case, ceramic tiles, polycarbonate, plystyrene, etc. Also, it offers various ways of printing the white when material is transparent or colorful and allows to print the three-layer spot colors which means printing color-white-color at one time. The printheads are Ricoh Gen5 7pl,Gen6 5pl.The printing colors are Lc Lm Y M C K , White. Vanish available on All Ricoh heads.

The H1000 new linear motor printer now optionally includes a 600dpi CCD sets. By scanning the exact position and shape of the printing media, the real-time correction of the print head motion trail is processed algorithmically, thereby ensuring accurate printing at any position and at any angle.

Contact

© 2021 SHANGHAI DOCAN TECHNOLOGIES Co., Ltd. All Rights Reserved.