R5200 (5m UV RTR Printer)

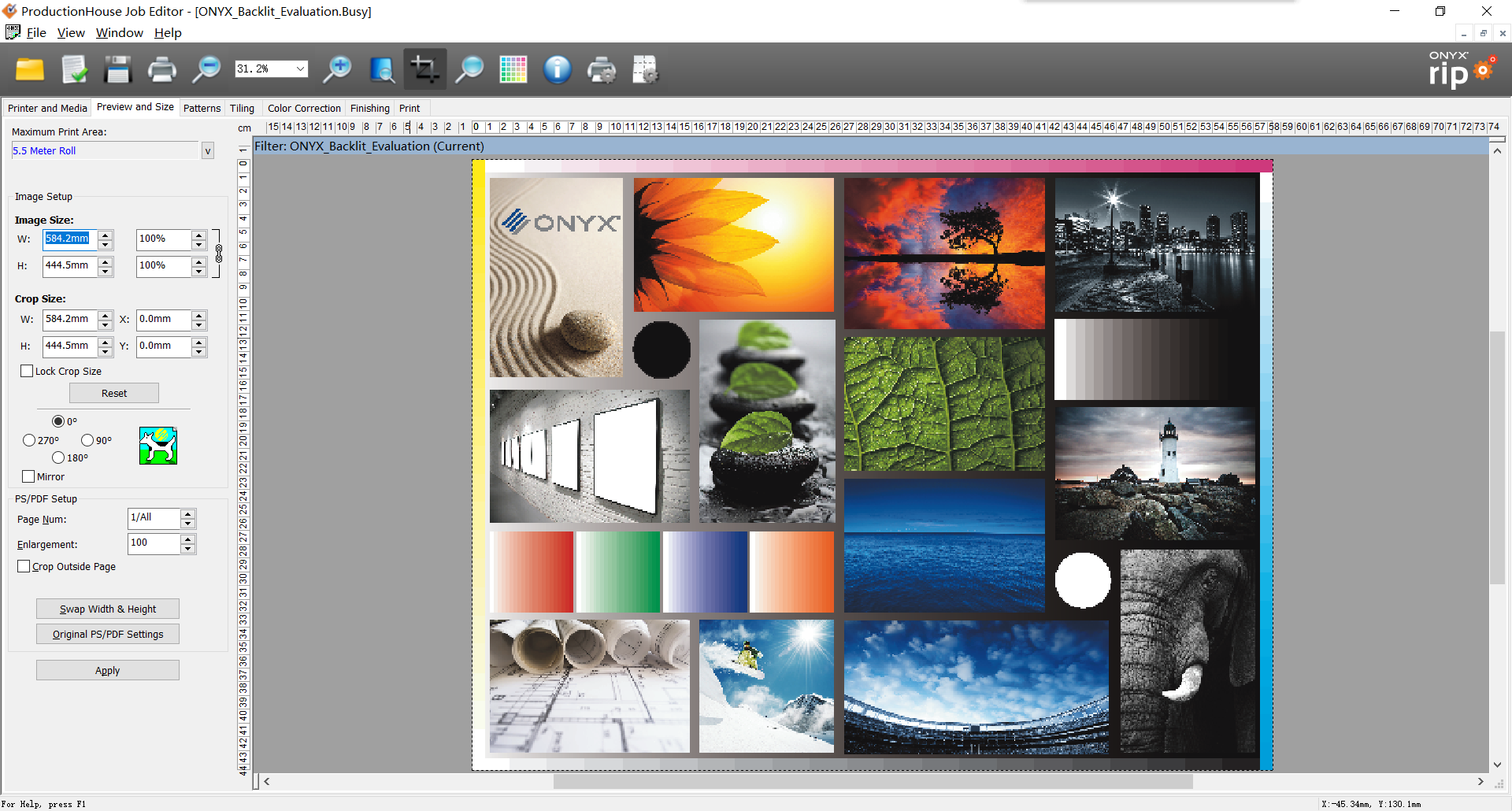

Print Size: 5000mm

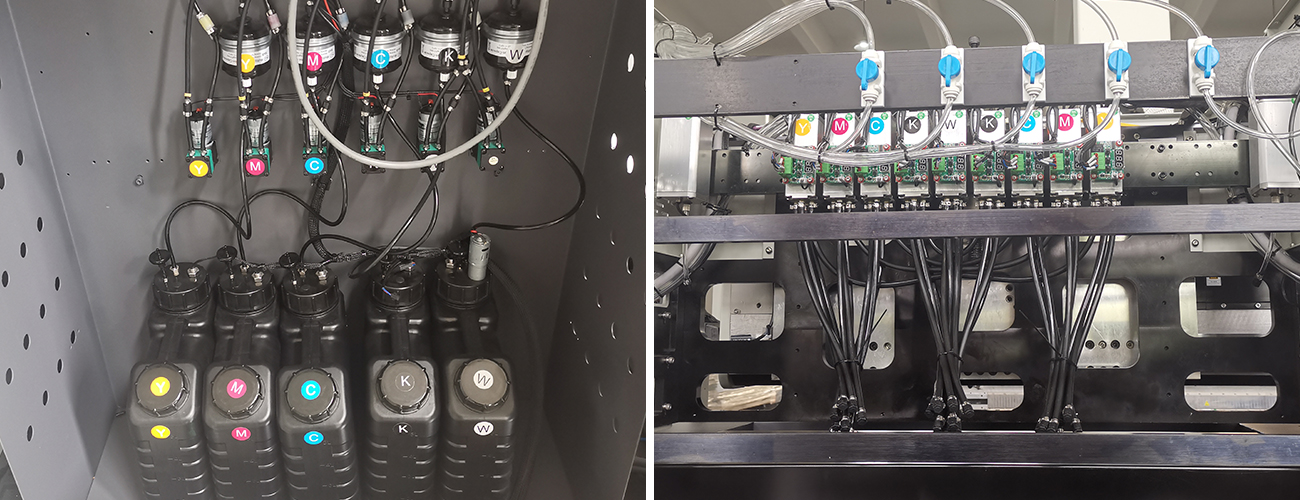

Colors: CMYK, White, LcLm

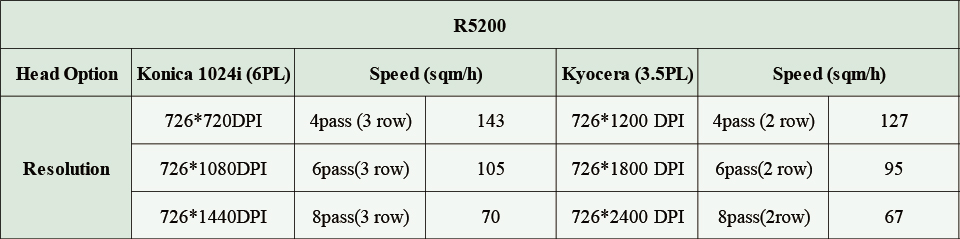

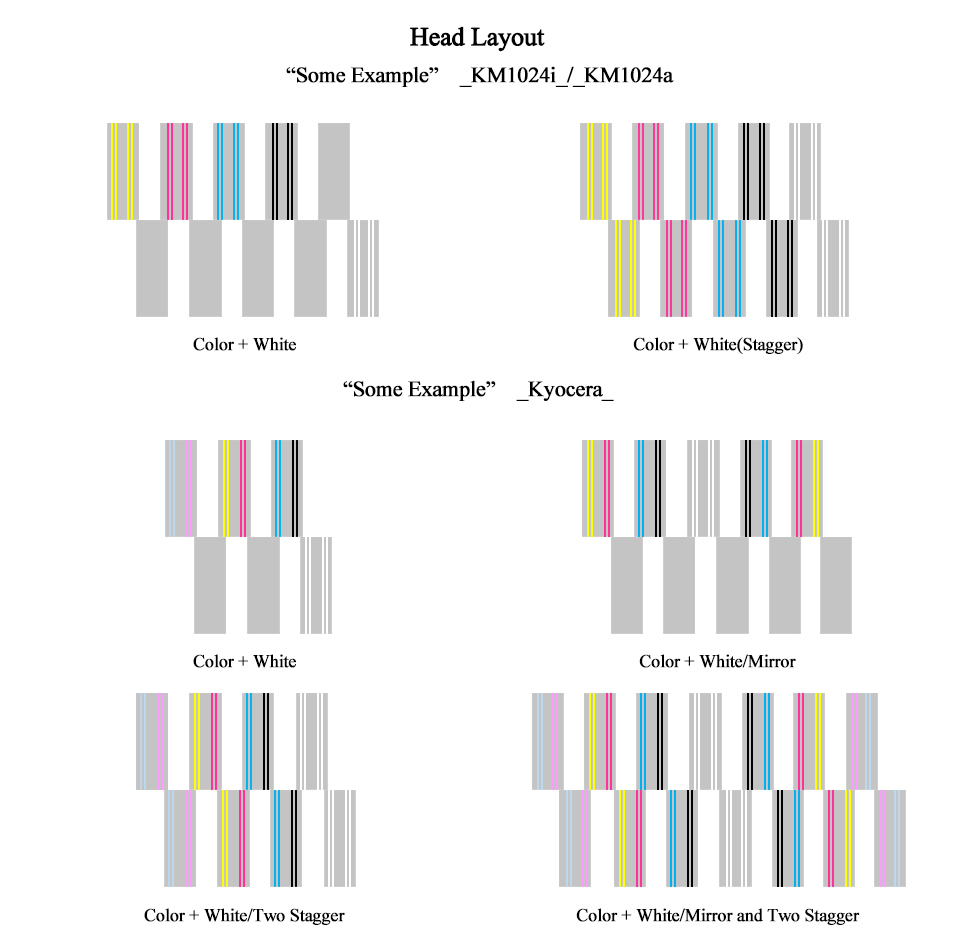

Printhead: KONICA KM1024I/ KYOCERA KJ4A

Print Speed: Up to 130 ㎡/hr

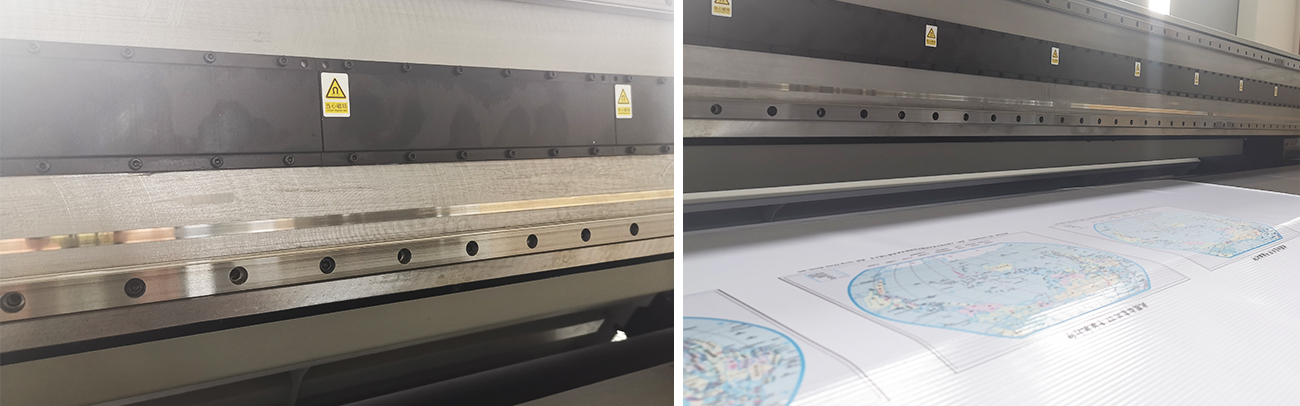

1.High performance linear motor&Metal Raster System

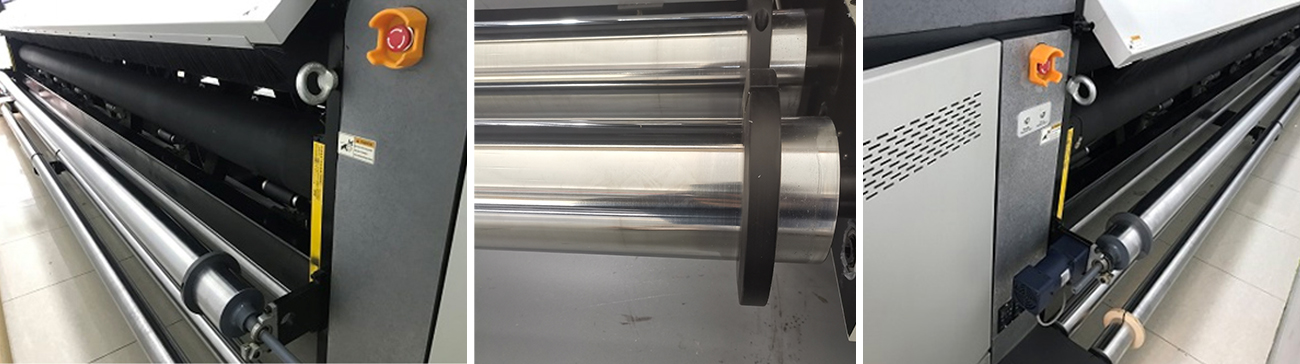

2.Dual servo motors feeding system

3.Suction Adjustable System

4.4pcs large-diameter rubber rollers minimize deflection

5.Simultaneous printing on multiple rolls up to 3

6.LED light Box System

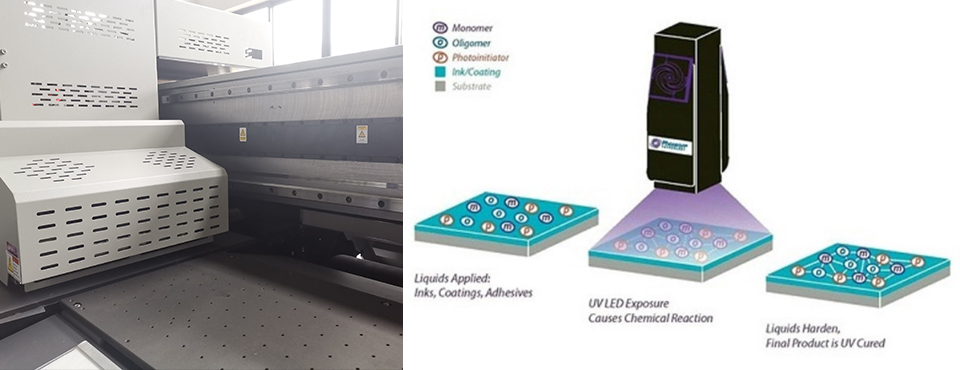

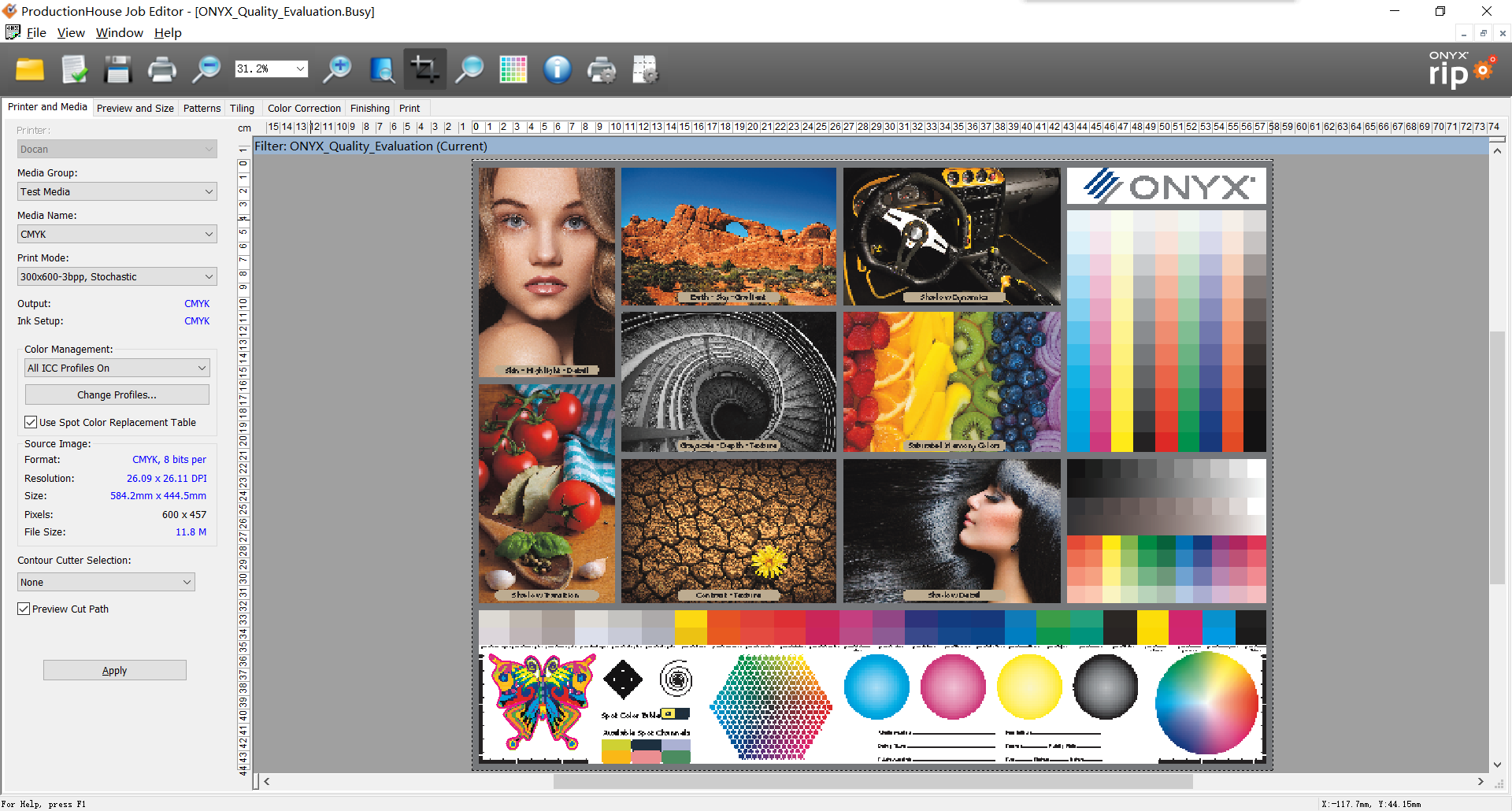

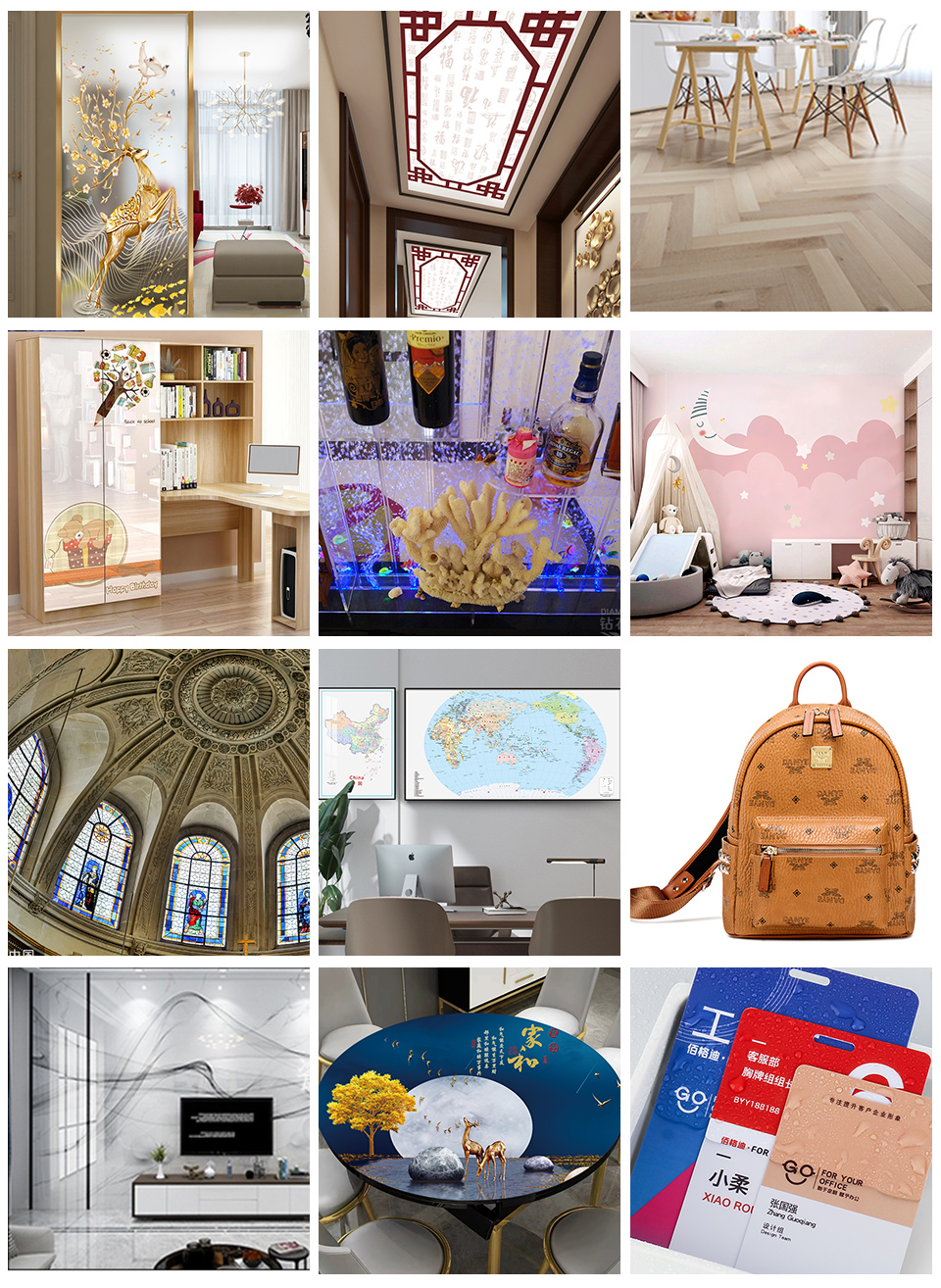

R5200 provides the widest UV digital printing possibility in the market. With its contactless working Magnetic Head Transport System handling with high quality printings fast on 5200mm wide flexible materials makes it is ideal for building cladding, backstage decor, etc. It can print narrower medias accurately as well. Its technical features, capabilities and well structured case allows it to full-time work when high performance is necessary.Using UV ink can produce excellent images on various materials like banners, vinyl, one-way vision, foil, backlit fabric, etc. The ink is environment friendly. Also, it offers various ways of printing the white when the material is in color and allows to print the three-layer spot colors which means printing color-white-color at one time. The printhead options are Konica Minolta 1024i 6-13pL and Kyocera KJ4A 3.5 pL . The printing colors are Lc Lm Y M C K , White are optionals!

Contact

© 2021 SHANGHAI DOCAN TECHNOLOGIES Co., Ltd. All Rights Reserved.