H1600M (High Speed UV Flatbed)

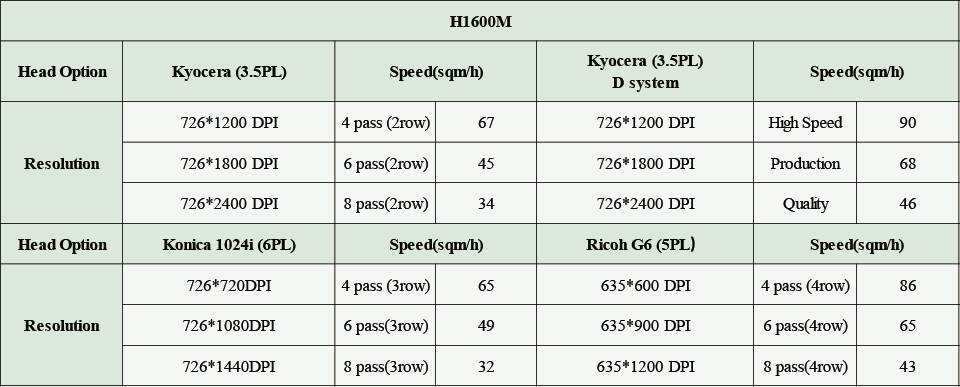

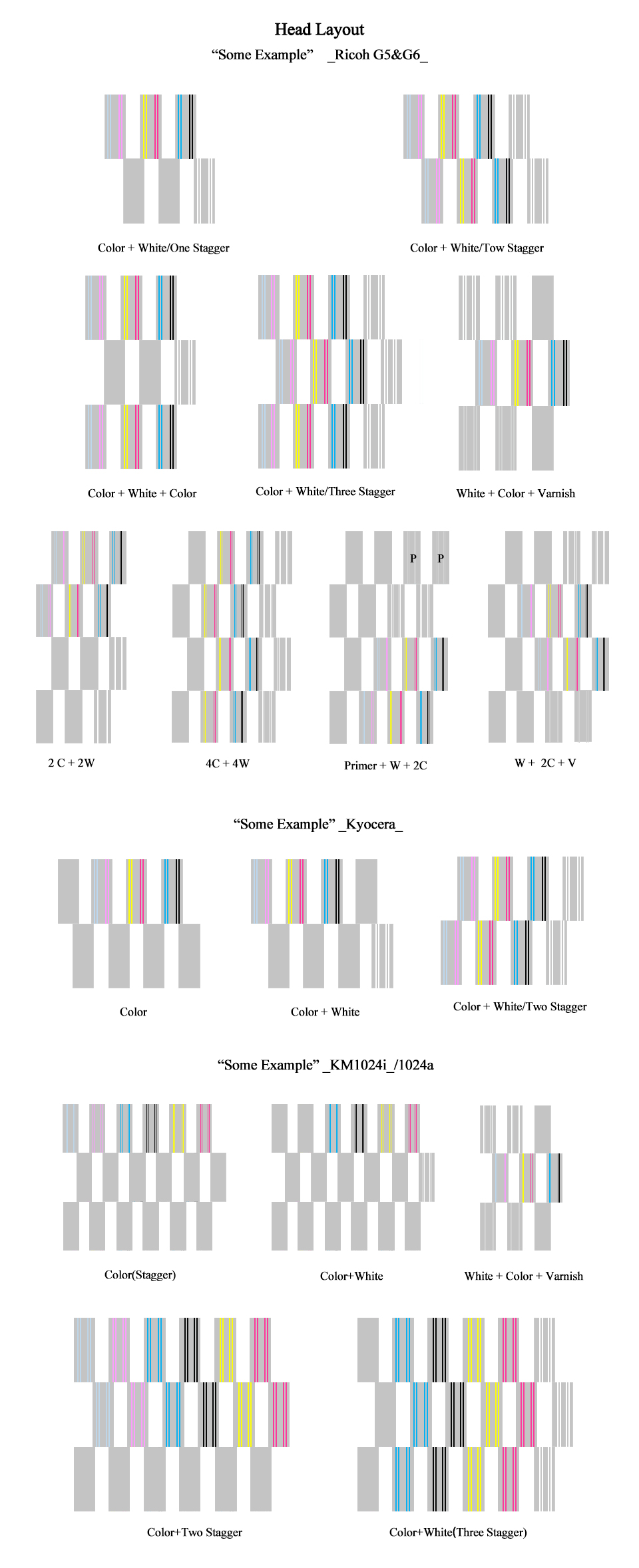

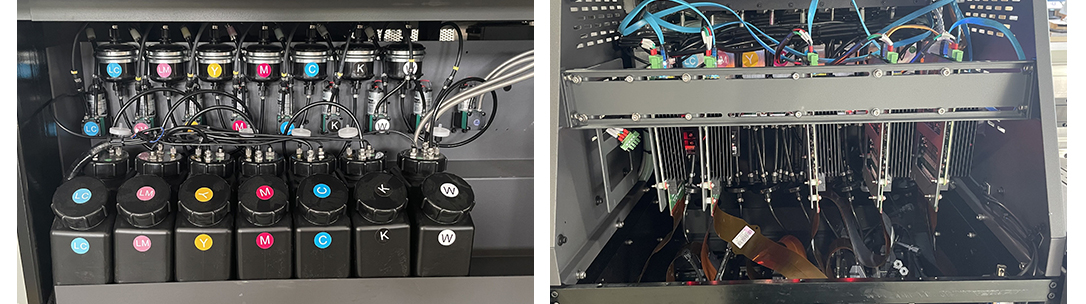

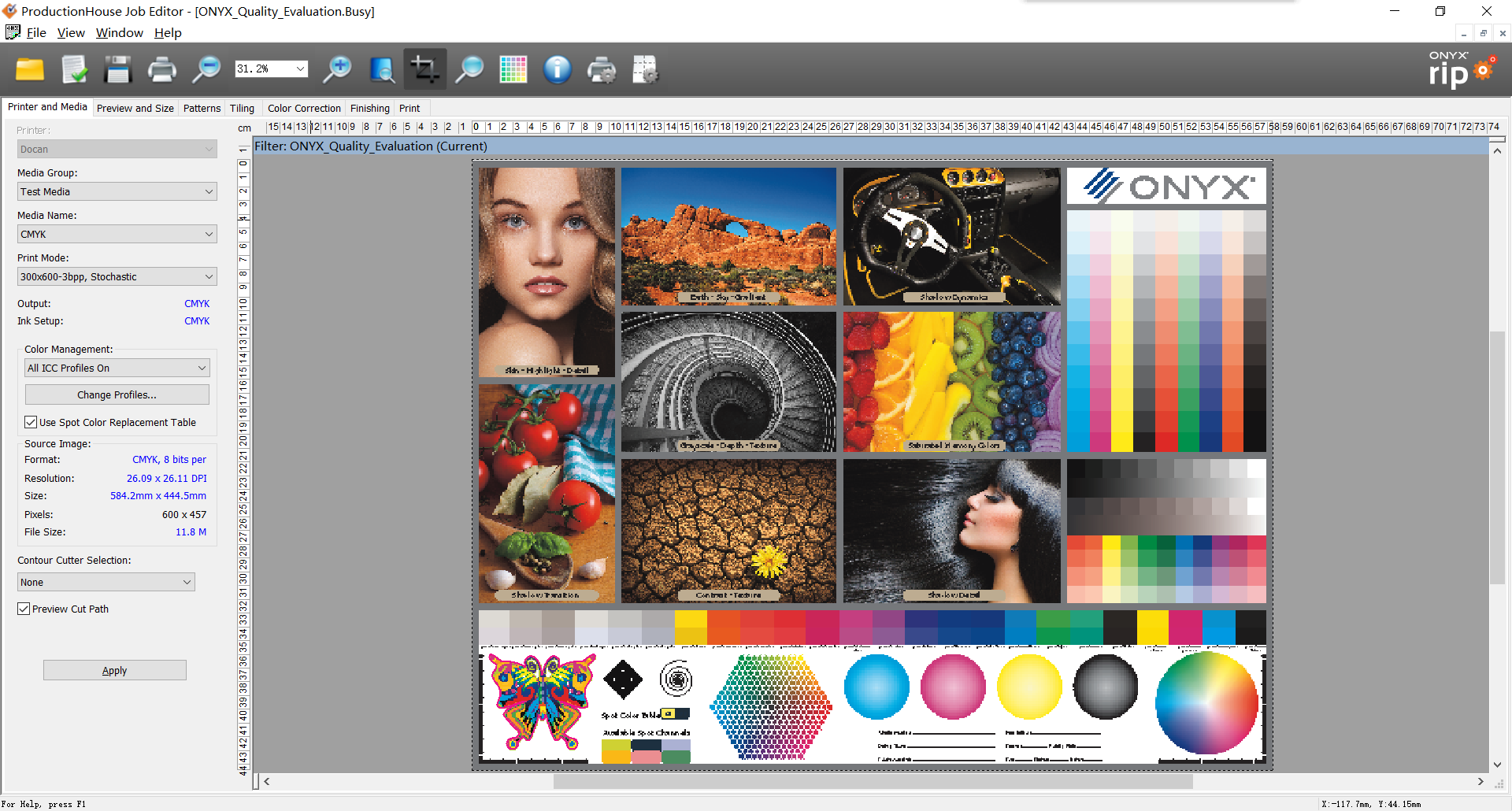

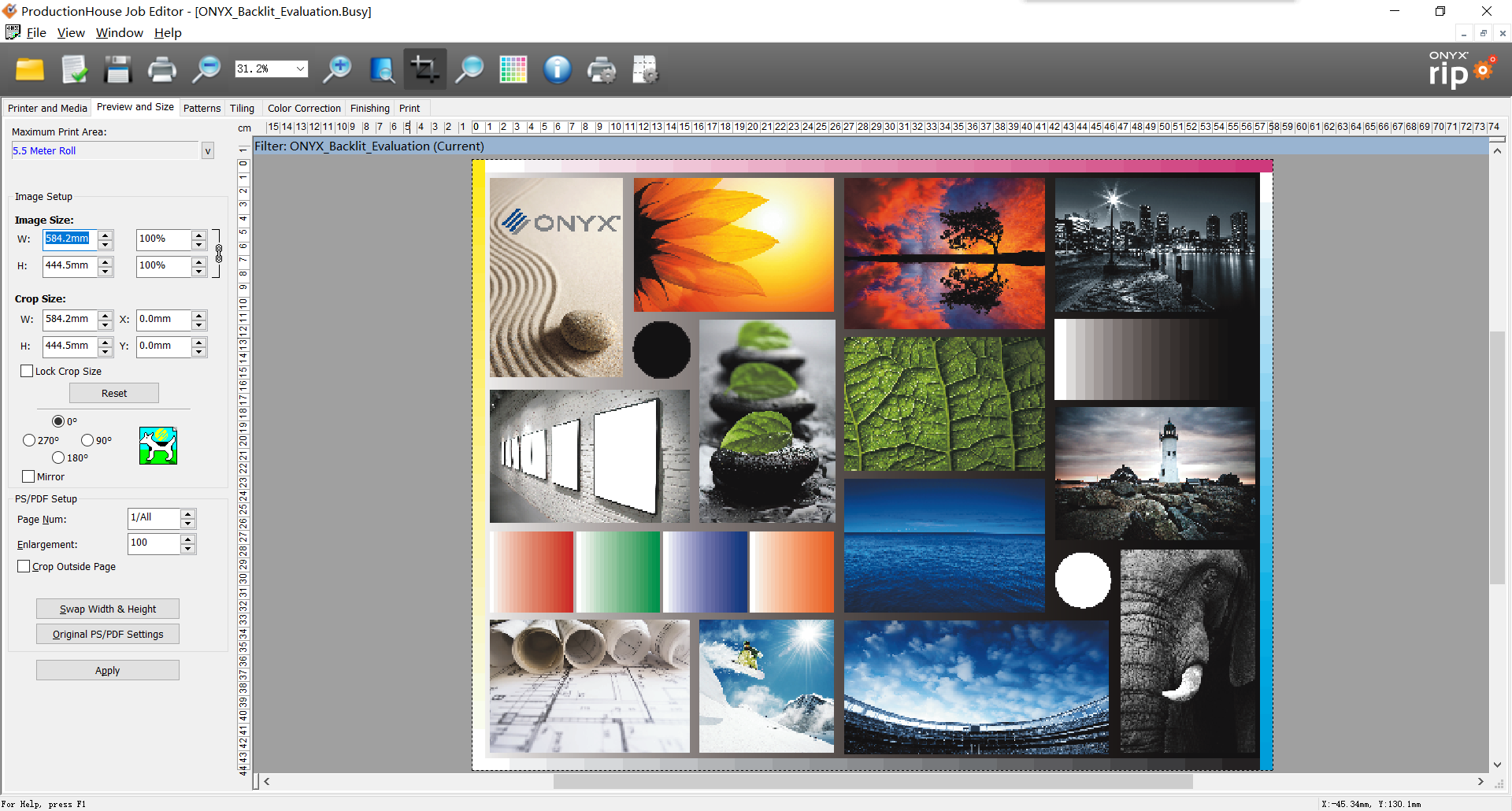

Printhead: KYOCERA KJ4A and Ricoh Gen6 ,Konica 1024i /1024A optional

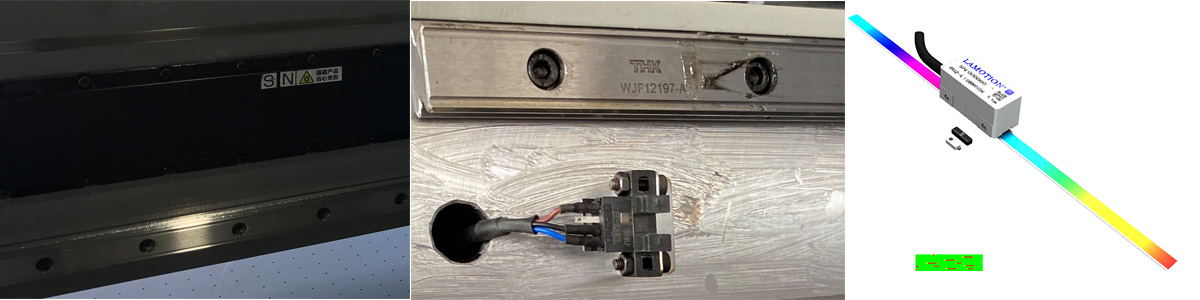

1.High Performance Linear motor&Metal Raster strip

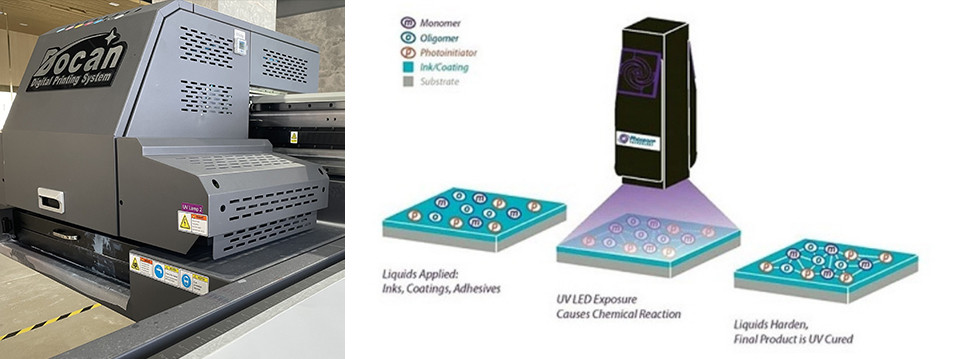

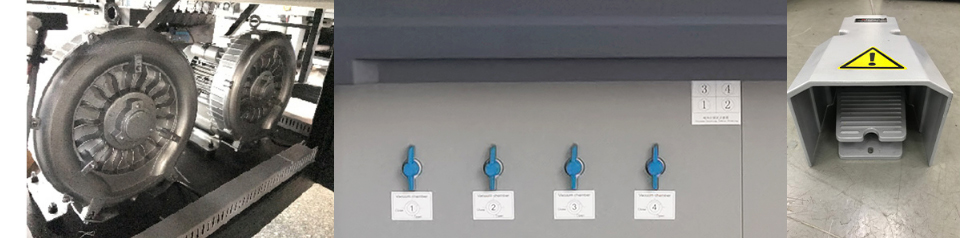

2.High light Led lamp with water cooling system

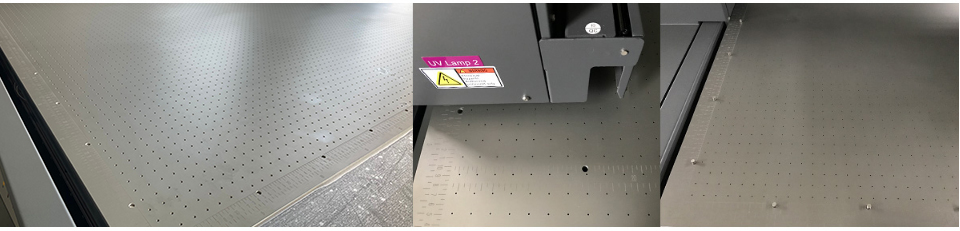

3.Media vacuum suction system

4.White ink Recirculation System

5.Automatic Registration Pin System

6.Automatic height detection system

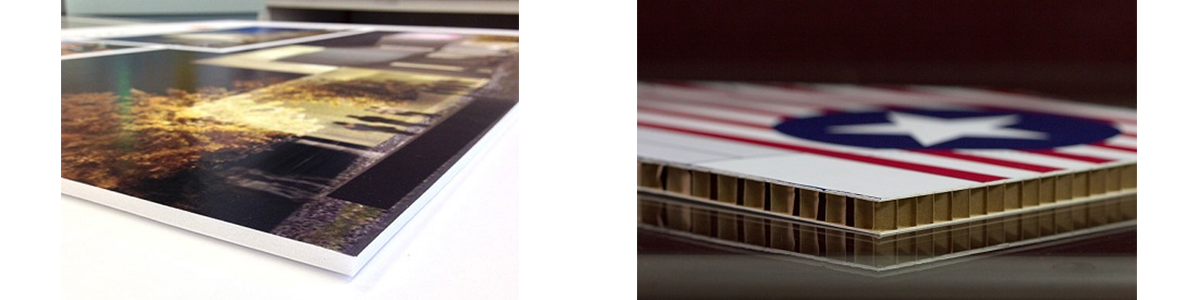

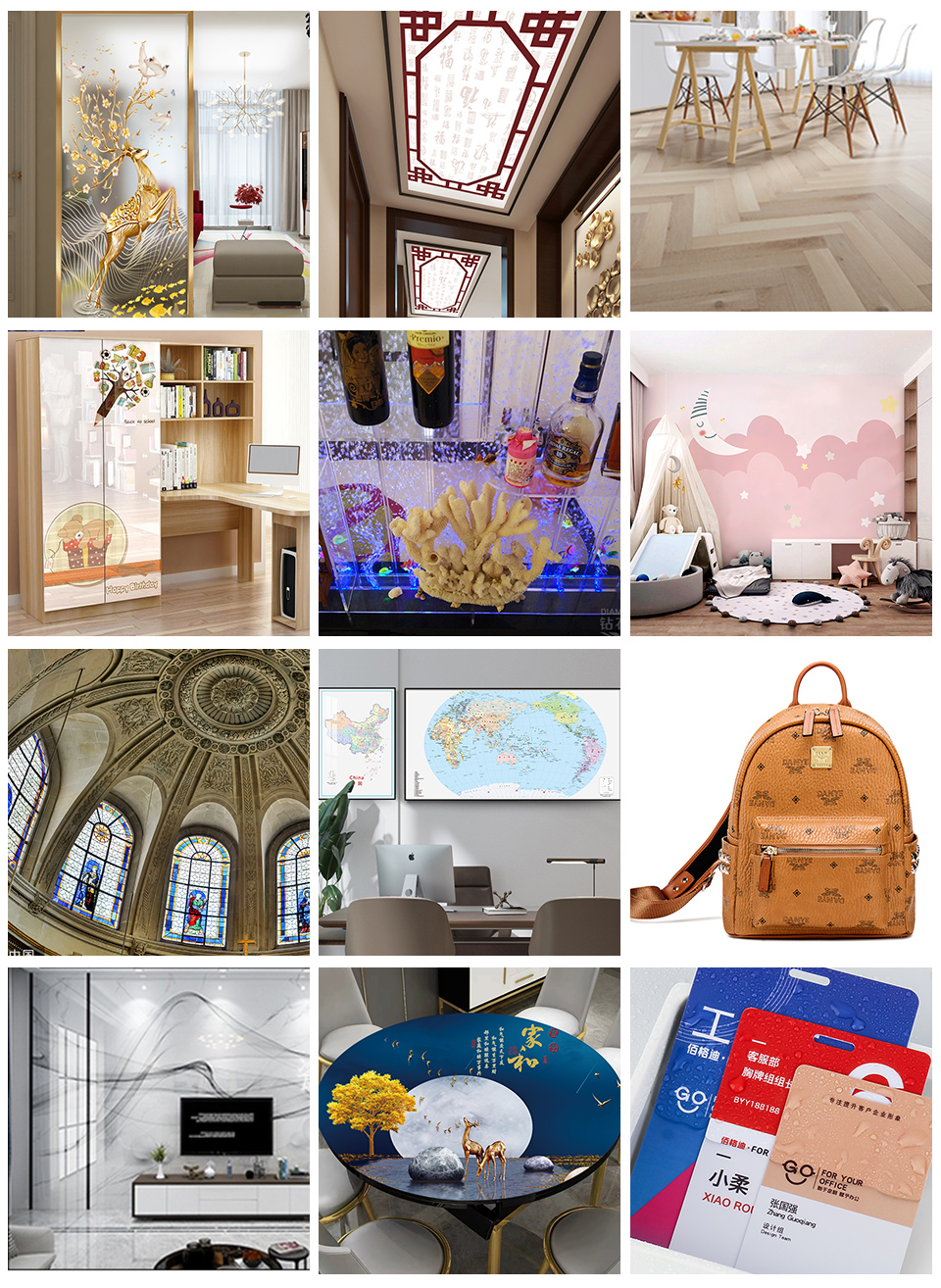

H1600M UV is the most comprehensive and innovative flatbed UV digital printer in our range. With its new designed and well structured case, THK guide rail and 2500 x 1250mm print area is ideal for facilities handling full-time industrial operations. It is able to print on heavy matel or wooden sheets up to 200 kg. Using the UV ink it can print excellent images on various rigid medias, such as glass, acrylic, wood, PVC foam board, KT board, MDF, aluminium, cellphone case, ceramic tiles, polycarbonate, plystyrene, etc. Also, it offers various ways of printing the white when material is transparent or colorful and allows to print the three-layer spot colors which means printing color-white-color at one time. The printhead are Ricoh Gen6 5pl ,konica 1024i 6-13 pl and Kyocera KJ4A 3.5pL optional. The printing colors are Lc Lm Y M C K , White. Vanish available on All Ricoh heads.

Contact

© 2021 SHANGHAI DOCAN TECHNOLOGIES Co., Ltd. All Rights Reserved.