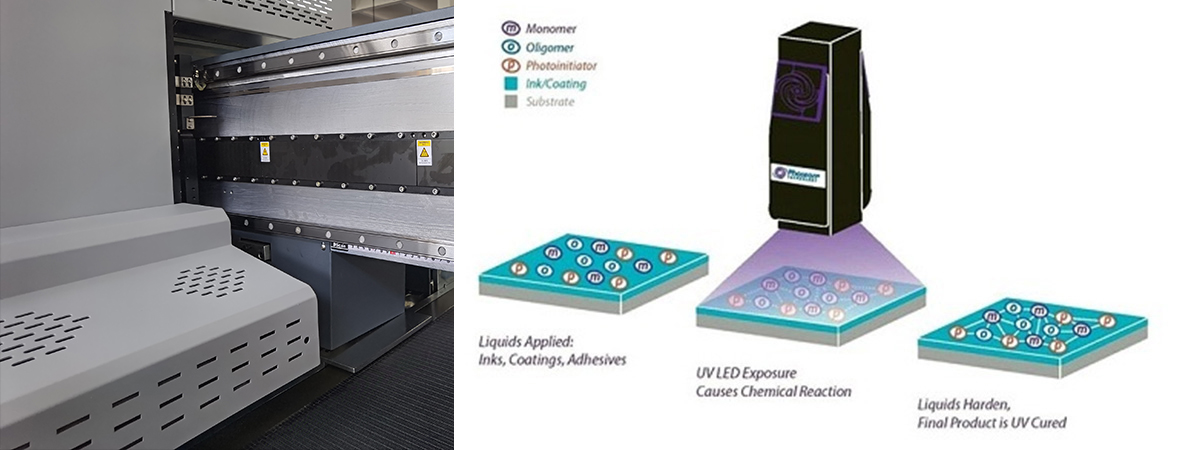

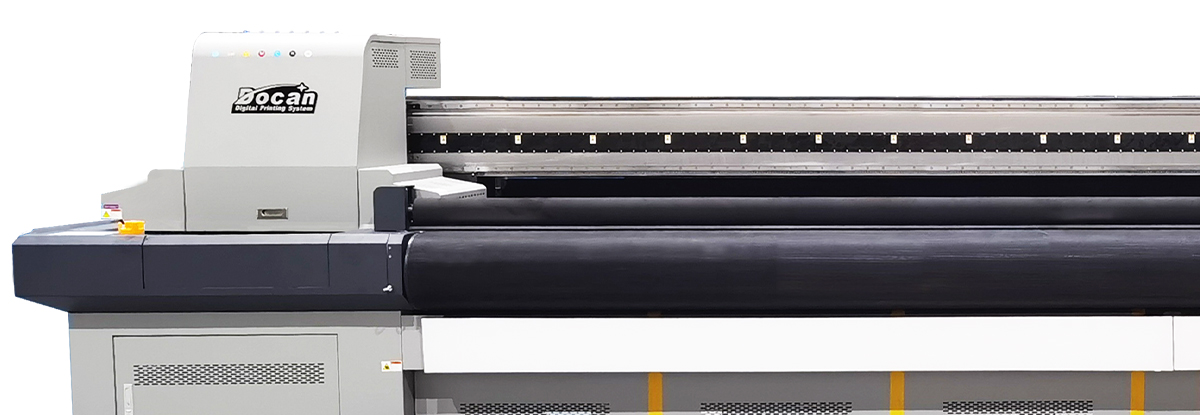

FR5000 (5m UV Hybrid)

Print Size:5000mm

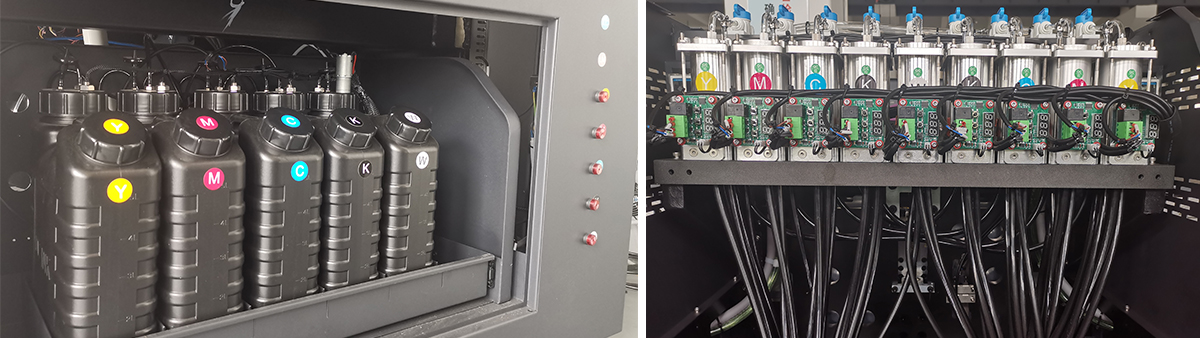

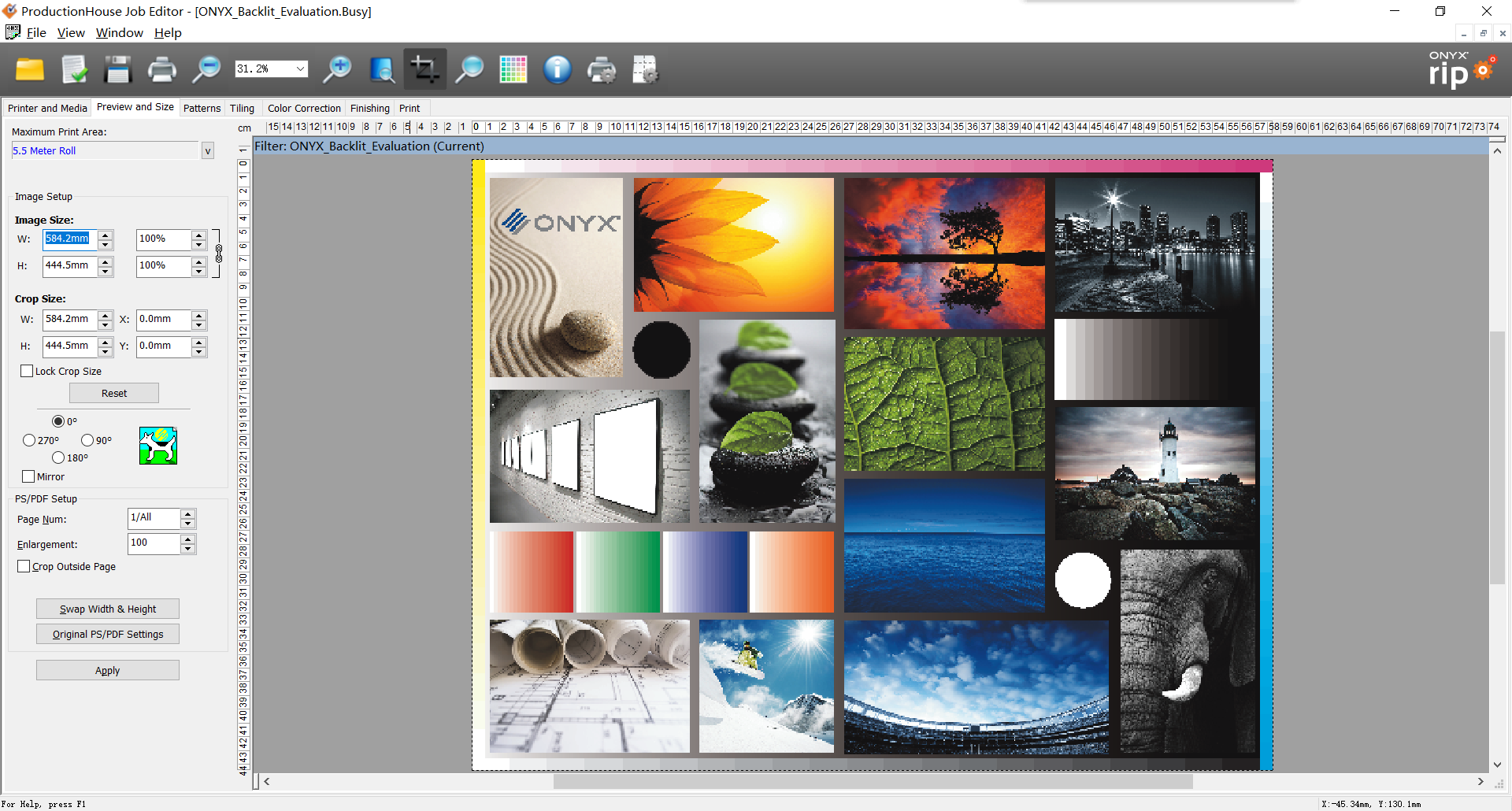

Colors: CMYK, White,LcLm

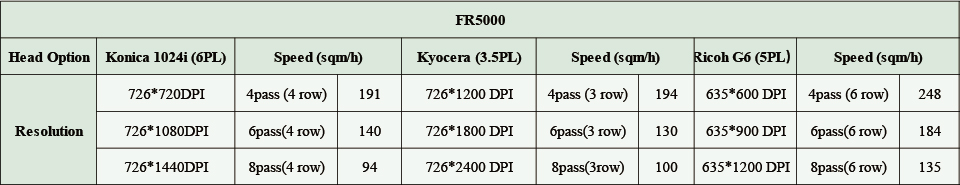

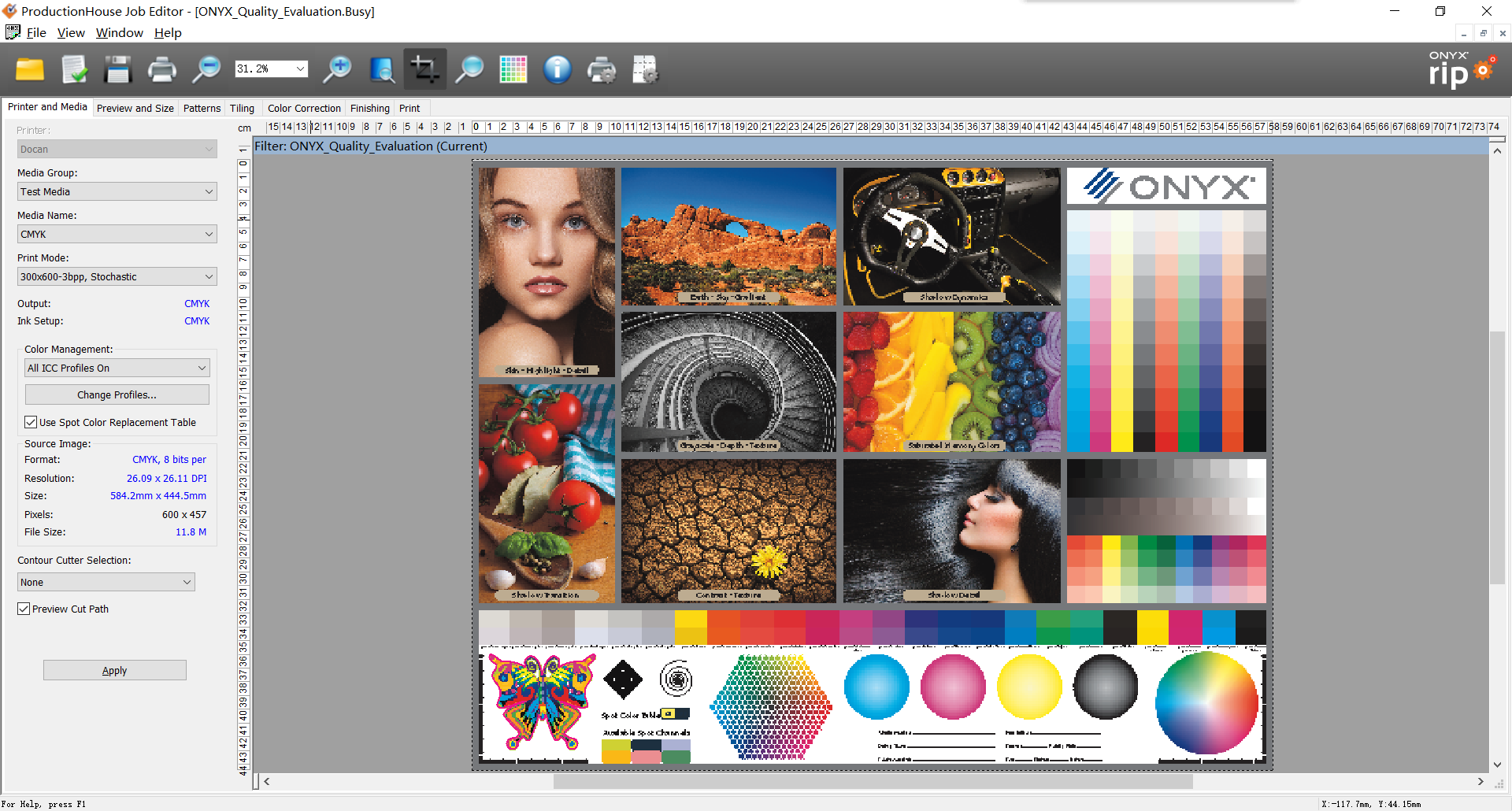

Printhead: KONICA KM1024I/1024a/KYOCERA KJ4A

Print Speed: Up to 200 ㎡/hr

1.High performance linear motor

2.Anti-crash Sensor, Resume print after E-stop

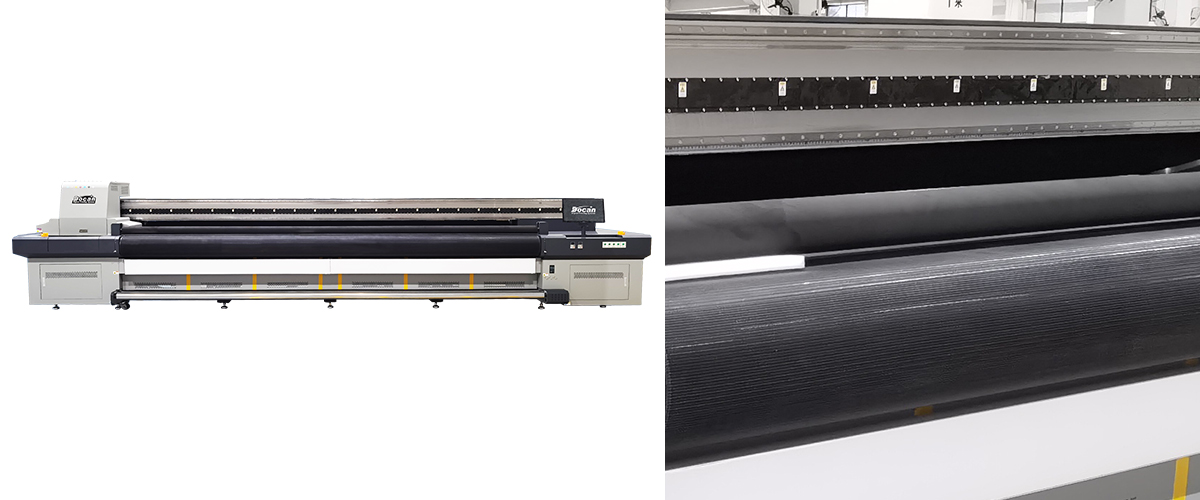

3.Vacuum Convey-belt System

4.Industrial Take up & Feeding System

5.Belt automatic deviation correction Function

6.Auto ink volum alarm system

7.Anti-static Bar

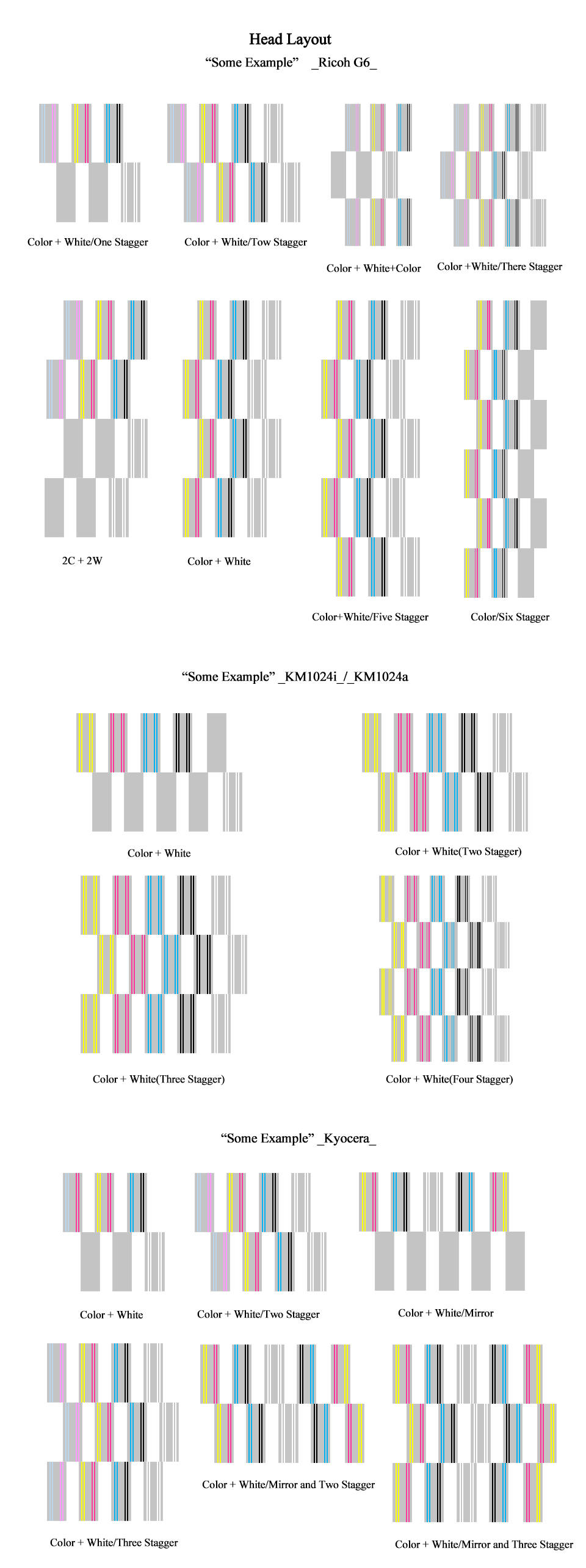

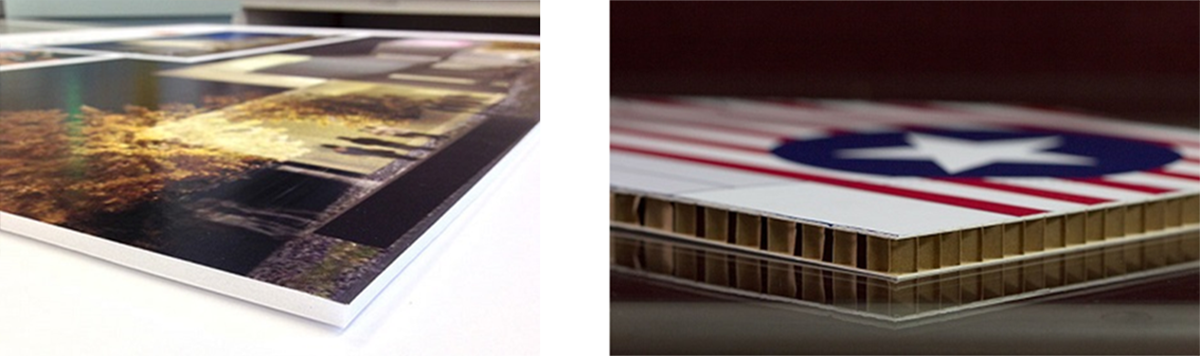

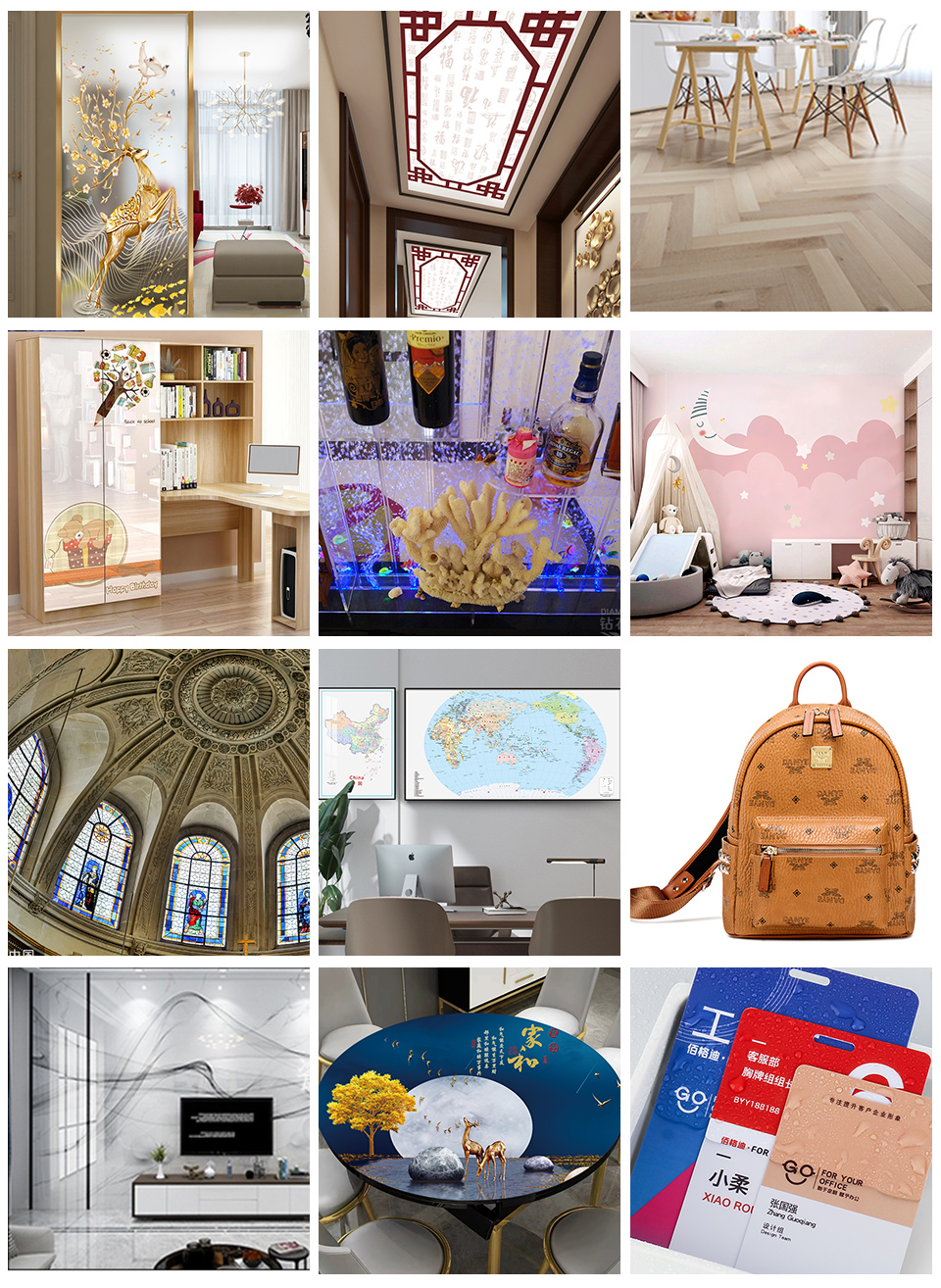

FR5000 UV Hybrid printer is a huge heavy duty belt-conveyed UV printing machine, which is designed mainly for both roll to roll printing and board sheet printing. 5m print width offers a solution for multiple smaller size media to print at the same time. With extension tables at the back and front, FR5000 can print unlimited length of rigid and flexible medias due to the vacuum belt feeding and conveying system. Using the UV ink, it can print excellent images on various rigid medias, such as glass, acrylic, wood, PVC foam board, KT board, polycarbonate, MDF, aluminium, cellphone case, ceramic tiles, and flexbilematerials like banners, vinyl, and so on. Also, they offer various ways of printing the white color, and can print the three-layer spot colors which means printing color-white-color at one time. The printhead options are Konica Minolta 1024i 6-13pL and KyoceraKJ4A 3.5pL . The printing colors are Lc Lm Y M C K , White is optional!

Contact

© 2021 SHANGHAI DOCAN TECHNOLOGIES Co., Ltd. All Rights Reserved.